Understanding Hydraulic Jacks and Their Uses

Hydraulic jacks are powerful tools that help you lift heavy objects with ease. They work on the principle of pressure transmission in fluids, allowing for minimal effort when raising loads. You’ll find various types, like bottle and floor jacks, used in automotive repair and construction. Safety is key; always check for stability and weight limits. If you’re curious about their key components and innovations, you’ll discover plenty more exciting information ahead.

Key Takeaways

- Hydraulic jacks lift heavy objects efficiently using hydraulic fluid and Pascal’s principle of pressure transmission.

- Key types include bottle jacks, floor jacks, scissor jacks, and hydraulic car lifts, each designed for specific applications.

- Common uses encompass lifting equipment, stabilizing foundations, hoisting steel beams, and supporting formwork during construction.

- Safety practices include regular inspections, avoiding load limits, and always using jack stands for stability under lifted loads.

- Innovations in hydraulic jacks feature smart sensors, wireless controls, and eco-friendly fluids, enhancing functionality and user safety.

What Is a Hydraulic Jack?

A hydraulic jack is a powerful tool designed to lift heavy objects with ease. You might find it in garages, construction sites, or even at home for various lifting tasks.

This tool operates using a simple lever system and hydraulic fluid, making it efficient and reliable. You can use a hydraulic jack to lift vehicles for tire changes, heavy appliances, or other cumbersome items that you’d struggle to move manually.

When using one, safety’s vital, so always verify the jack is on a stable surface and rated for the weight you plan to lift.

With just a bit of pressure applied, you can watch the jack effortlessly elevate the weight, making your lifting tasks considerably easier.

The Principles of Hydraulics

How does the hydraulic system manage to lift such heavy loads with minimal effort? It’s all about Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. Fundamentally, a small force applied to a smaller area creates a larger force over a bigger area. This is what allows you to lift significant weights easily.

Here’s a quick breakdown of the principles involved:

| Principle | Explanation |

|---|---|

| Pascal’s Principle | Pressure in fluids is equal everywhere. |

| Force Multiplication | Smaller force creates larger lift. |

| Area Ratio | Larger area = more lifting power. |

| Fluid Incompressibility | Fluids transmit force without losing volume. |

These principles are the foundation of how hydraulic jacks function efficiently.

Types of Hydraulic Jacks

There are several types of hydraulic jacks, each designed for specific applications and weight capacities. The most common type is the bottle jack, which is compact and is great for lifting heavy vehicles.

Then there’s the floor jack, typically used in garages, which has a wider base for stability and can lift cars with ease.

Scissor jacks are small and portable, often found in emergency kits for changing tires.

If you need to lift heavy structures, a hydraulic car lift is your best bet, providing a safe way to elevate vehicles for maintenance.

Ultimately, toe jacks are designed for lifting machinery by sliding under equipment, making them ideal for industrial applications.

Choosing the right jack can make all the difference in safety and efficiency.

How Hydraulic Jacks Work

Understanding the mechanics behind hydraulic jacks reveals the simplicity and efficiency of this powerful lifting tool. Hydraulic jacks operate on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted equally in all directions. When you pump the jack handle, you push fluid through the system, creating pressure. This pressure lifts the load because of the larger surface area of the jack’s lifting cylinder compared to the smaller pumping cylinder.

| Action | Effect |

|---|---|

| Pumping the handle | Generates hydraulic pressure |

| Pressure increase | Lifts the load |

| Release valve | Lowers the load |

This simple yet effective principle allows hydraulic jacks to lift heavy objects with minimal effort.

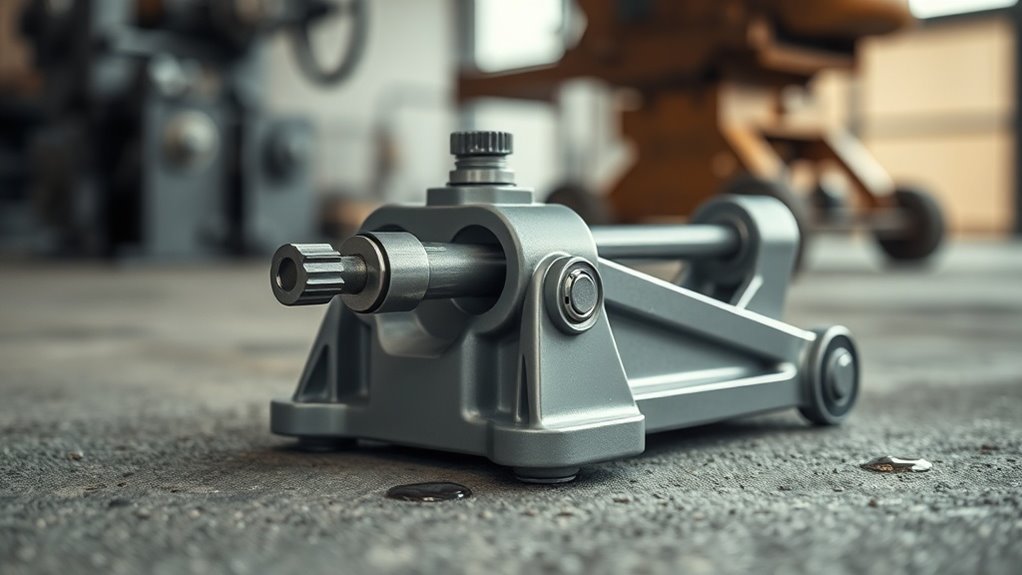

Key Components of a Hydraulic Jack

A hydraulic jack consists of several key components that work together to enable efficient lifting.

The main part is the cylinder, where hydraulic fluid is pressurized to create force. You’ll also find a piston inside the cylinder, which moves up and down to lift the load. The hydraulic fluid plays a vital role, transmitting the pressure from the piston to generate lift.

There’s a pump that helps draw fluid into the cylinder, and a release valve that lets you lower the jack after use. Additionally, the base provides stability during operation, while the handle allows you to operate the jack easily.

Understanding these components helps you appreciate how a hydraulic jack functions effectively for lifting tasks.

Safety Tips for Using Hydraulic Jacks

When using hydraulic jacks, it’s crucial to prioritize safety to prevent accidents and injuries.

Here are some critical tips to keep in mind:

- Always inspect your jack before use, ensuring it’s not damaged or leaking.

- Use the jack on stable, level ground to avoid tipping or sliding.

- Never exceed the jack’s weight limit; doing so can lead to failure.

- Always place jack stands under the load after lifting to provide extra stability.

Common Applications in Automotive Repair

When you’re working on your vehicle, hydraulic jacks are invaluable for lifting it safely during maintenance tasks.

Whether you’re changing a tire or performing routine checks, having the right equipment makes all the difference.

Understanding how to use these jacks effectively can simplify your automotive repairs.

Lifting Vehicles for Maintenance

Many mechanics rely on hydraulic jacks to lift vehicles for maintenance tasks efficiently.

These powerful tools allow you to access areas underneath the car with ease, making repairs and inspections quicker.

Whether you’re working in a professional garage or tackling a DIY project, hydraulic jacks are indispensable.

Here are some common applications:

- Changing oil: Easily reach the oil pan for a smooth drain.

- Inspecting brakes: Get a clear view to verify safety and functionality.

- Replacing exhaust systems: Access tight spaces without hassle.

- Performing suspension work: Lift the vehicle securely while you attend to vital parts.

Using a hydraulic jack not only saves time but also enhances your safety during repairs.

Tire Change Procedures

Changing a tire is one of the most essential skills every driver should possess. First, gather your tools: a hydraulic jack, lug wrench, and spare tire. Confirm your vehicle’s on a flat surface and set the parking brake.

Loosen the lug nuts slightly but don’t remove them yet. Next, position the hydraulic jack under the vehicle’s lift point and raise it until the tire clears the ground.

Now, fully remove the lug nuts and take off the flat tire. Place the spare tire onto the wheel hub, tightening the lug nuts by hand.

Finally, lower the vehicle and tighten the lug nuts securely in a crisscross pattern. Always check the spare’s pressure before hitting the road again.

Hydraulic Jacks in Construction

When you’re working in construction, understanding the various types of hydraulic jacks is vital for your tasks.

You’ll discover their applications range from lifting heavy materials to supporting structures, but safety can’t be overlooked either.

Let’s explore how these tools can make your job easier and safer.

Types of Hydraulic Jacks

Understanding the various types of hydraulic jacks is essential for anyone involved in construction.

These jacks differ in design and purpose, catering to a wide range of lifting needs. Knowing their unique features can enhance your projects and improve efficiency.

- Bottle Jacks: Compact and portable, great for elevating heavy loads.

- Floor Jacks: Typically used for vehicles, they offer stability and quick lifting.

- Scissor Jacks: Ideal for tight spaces, they provide elevation through a crisscross mechanism.

- High-Lift Jacks: Perfect for off-road use, they can lift vehicles far above the ground.

Familiarizing yourself with these options helps you choose the right jack for every construction task, ensuring safety and effectiveness.

Applications in Construction

Hydraulic jacks play an essential role in various construction applications, making tasks more efficient and safer. You’ll find these versatile tools used for lifting heavy equipment, setting foundations, and even hoisting steel beams during installations. Their ability to exert powerful force allows for precision and control in tight spaces, which can save time on the job site.

Here’s a quick overview of hydraulic jack applications in construction:

| Application | Purpose | Benefits |

|---|---|---|

| Lifting Equipment | Elevate machinery | Reduces labor effort |

| Foundation Setting | Stabilizes structures | Guarantees level support |

| Steel Beam Hoisting | Supports frame erection | Enhances safety |

| Leveling Surfaces | Adjusts ground height | Improves workflow |

| Formwork Support | Holds molds in place | Increases accuracy |

Safety Considerations in Use

While hydraulic jacks substantially enhance efficiency in construction tasks, guaranteeing safety during their use is paramount.

To avoid accidents, keep these safety tips in mind:

- Always inspect the jack before use, checking for any signs of wear or damage.

- Ensure the load is stable and properly balanced before lifting.

- Never exceed the jack’s weight limit; know the specifications.

- Use jack stands to support heavy loads after lifting; don’t rely solely on the hydraulic system.

Maintenance and Care for Hydraulic Jacks

To guarantee your hydraulic jack operates efficiently and lasts for years, regular maintenance is essential.

Start by inspecting the jack regularly for any signs of wear or damage, including cracks or leaks. Clean the jack after each use to prevent dirt and grime buildup, which can affect its performance.

Make sure to check the hydraulic fluid levels; if they’re low, refill them with the recommended type of fluid. Keep the moving parts lubricated to ascertain smooth operation.

When not in use, store the jack in a dry, cool place to avoid rust and corrosion.

Finally, follow the manufacturer’s guidelines for periodic servicing.

Innovations in Hydraulic Jack Technology

Taking care of your hydraulic jack is only part of the equation; advancements in hydraulic jack technology are reshaping its performance and usability.

You’ll appreciate how these innovations enhance your experience:

- Smart sensors that monitor weight and pressure for added safety

- Wireless controls for remote operation, making heavy lifting easier

- Compact designs for better portability and storage, fitting easily in your vehicle

- Eco-friendly fluids that improve efficiency while protecting the environment

These features not only boost functionality but also contribute to a safer working environment.

Staying updated with these advancements guarantees you get the most out of your hydraulic jack, making your tasks more efficient and manageable, whether you’re a DIY enthusiast or a professional mechanic.

Questions

Can Hydraulic Jacks Be Repaired if They Break?

Yes, hydraulic jacks can be repaired if they break. It often depends on the extent of the damage. You might need to replace seals or components, but many issues can be fixed with proper maintenance.

What Materials Are Commonly Used in Hydraulic Jacks?

Hydraulic jacks commonly use materials like steel for structural components, rubber for seals, and various alloys for pistons. These materials guarantee durability and efficiency, so you can trust your jack to perform when you need it.

How Do I Choose the Right Hydraulic Jack for My Needs?

When it comes to choosing the right hydraulic jack, you’ll want to contemplate your load requirements, height range, and portability. Make sure it fits your needs, or you’ll find yourself in over your head!

Are Hydraulic Jacks Portable for On-The-Go Use?

Yes, hydraulic jacks can be portable for on-the-go use. They come in various sizes, so you can choose lightweight options that fit easily in your vehicle, making it convenient for emergencies or tire changes.

How Do Weather Conditions Affect Hydraulic Jack Performance?

Weather conditions can greatly affect hydraulic jack performance. Extreme temperatures can impact fluid viscosity, causing jacks to work less efficiently. You’ll want to monitor the environment and adjust your usage accordingly for ideal effectiveness.

Conclusion

In conclusion, hydraulic jacks are versatile tools that simplify lifting heavy loads, making them essential in various fields like automotive and construction. Just remember, “a stitch in time saves nine”—regular maintenance will help you avoid bigger problems down the line. By understanding the principles and applications of hydraulic jacks, you’re better equipped to use them effectively and safely. So, whether you’re fixing a car or working on a job site, a reliable hydraulic jack is your best friend.