Basics of Crimping Tools for Electrical Work

Crimping tools are essential for creating strong, permanent electrical connections without the hassle of soldering. They compress metal components together for a secure bond and come in various types, from standard pliers to specialized hydraulic crimpers. Choosing the right tool involves considering wire gauge compatibility and ergonomic features for comfort. Regular maintenance keeps them in top shape, ensuring safety and performance. There’s so much more to explore about crimping tools and their proper use.

Key Takeaways

- Crimping tools create strong, permanent electrical connections by compressing metal components together, eliminating the need for soldering.

- Various types of crimping tools exist, including standard, ratcheting, hydraulic, and specialized crimpers for specific tasks.

- Choosing the right tool requires assessing wire gauge compatibility and ergonomic features for user comfort and efficiency.

- Common crimping mistakes include using the wrong connector size, insufficient pressure, and neglecting to inspect tools before use.

- Maintaining crimping tools involves regular cleaning, lubrication, and proper storage to ensure performance and longevity.

What Are Crimping Tools?

Crimping tools are essential for anyone working with electrical connections. These specialized tools allow you to create strong, permanent connections between wires and connectors, ensuring a reliable electrical flow.

By compressing the metal components together, crimping tools eliminate the need for soldering while providing a secure bond that can withstand various stresses. You’ll find them in various sizes and designs, tailored for different wire gauges and connection types.

As you work on electrical projects, using crimping tools can greatly enhance the durability of your connections and streamline your workflow. Familiarizing yourself with these tools will save you time and reduce the risk of connection failure.

Types of Crimping Tools

There are several types of crimping tools designed for different tasks and applications in electrical work. The most common ones include standard crimping pliers, which handle most general tasks, and ratcheting crimpers, which provide consistent pressure for better connections.

If you’re working with heat-shrink terminals, you’ll want a specialized crimper that can handle that specific type. For more delicate wires, micro crimpers are available, ensuring precision without damaging the conductor.

Then there are modular crimpers, used primarily for Ethernet and telephone connections. If you’re dealing with heavy-duty tasks, look for hydraulic crimpers, as they offer high force while minimizing effort.

Each type has its purpose, so it’s important to understand these options for effective crimping in your projects.

Choosing the Right Crimping Tool

When you’re picking the right crimping tool, consider the type of tool that best suits your needs and the wire gauge you’ll be working with.

It’s also important to look for ergonomic features to guarantee comfort during use.

Making the right choices here can considerably impact your efficiency and results.

Tool Type Considerations

Selecting the right crimping tool is essential for achieving reliable electrical connections. You need to evaluate the type of connections you’ll be working with. For general use, a standard ratcheting crimping tool is often ideal, as it provides consistent pressure and ease of use.

If you’re tackling heavier-duty wires, a heavier model might be necessary to guarantee a secure crimp. Moreover, look for tools with interchangeable dies for versatility; they allow you to handle different terminal sizes and types without needing multiple tools.

If you’re focused on precision work, a smaller, manual crimper may suit your needs better. Ultimately, reflect on your specific projects and choose the crimping tool that best aligns with those requirements.

Wire Gauge Compatibility

Understanding wire gauge compatibility is vital for achieving ideal performance with your crimping tool. When you’re selecting a crimping tool, it’s important to match it with the wire gauges you’ll be working with. Each tool is designed for specific sizes, typically indicated in American Wire Gauge (AWG).

If your wire gauge exceeds the tool’s capacity, you risk poor connections or damaged wires. Conversely, using a tool on a wire that’s too small will lead to inadequate crimping.

Always check the specifications on the crimping tool to verify it accommodates the wire sizes you’re handling. Proper compatibility guarantees efficient work and secure, long-lasting connections.

Don’t skip this step; it can save you time and headaches down the line.

Ergonomic Features Importance

While a crimping tool’s functionality is essential, ergonomic features shouldn’t be overlooked, as they can greatly impact your comfort and efficiency during use.

An ergonomic design can help you avoid fatigue and strain, which is critical during extended projects.

Here are some key ergonomic features to keep in mind when choosing a crimping tool:

- Grip: Look for cushioned, non-slip handles that fit comfortably in your hand.

- Weight: Lighter tools reduce fatigue, especially during prolonged use.

- Handle Design: Tools with a pivoting handle improve leverage and reduce strain.

- Shape: A design that allows your wrist to remain in a natural position is essential for comfort.

Choose a tool that balances both functionality and ergonomics for the best results!

Crimping Tool Features and Specifications

When you’re in the market for a crimping tool, knowing the features and specifications can make all the difference in achieving reliable and secure electrical connections.

First, consider the type of crimping mechanism—simple squeeze or ratcheted. Ratcheted tools provide better control and consistent pressure, which is essential for quality results.

Consider whether you need a simple squeeze or a ratcheted crimping tool for optimal control and consistent results.

Look at the construction materials; high-carbon steel tools are more durable. Additionally, a tool with adjustable dies can accommodate various wire sizes and types.

Ergonomics also matter; padded grips can make extended use more comfortable.

Finally, don’t overlook any safety features, like locking mechanisms to prevent accidental use. Choosing the right features will guarantee you get a tool that meets your specific needs efficiently.

Understanding Crimp Connectors

Crimp connectors are essential components in electrical work, ensuring a strong and lasting connection between wires. Understanding these connectors is key to successful electrical projects.

Here are four important types of crimp connectors you should know:

- Butt Connectors: Great for connecting two wires end-to-end.

- Ring Connectors: Perfect for attaching to a terminal or stud.

- Splice Connectors: Ideal for joining multiple wires together.

- Bullet Connectors: Useful for quick and easy disconnection.

Choosing the right connector is vital for durability and conductivity. Always consider the application and the wire gauge when selecting. Additionally, performing regular continuity testing can help identify any weaknesses in your connections.

Properly matched connectors can make all the difference in performance, ensuring that your electrical connections are both reliable and safe over time.

How to Use Crimping Tools Correctly

Using crimping tools correctly guarantees reliable connections in your electrical work.

First, you’ll want to select the right connector for your project, then adjust your tool settings accordingly.

Finally, applying even pressure during crimping will help achieve a strong and secure connection.

Select Appropriate Connector

Selecting the right connector for your crimping needs is essential to guaranteeing a secure electrical connection. Using the wrong connector can lead to poor performance or even failure.

To help you choose wisely, consider these four factors:

- Wire Gauge: Verify the connector matches the wire gauge you’re working with.

- Connector Type: Decide if you need a ring, spade, or butt connector based on your application.

- Material: Opt for connectors made from copper or brass for maximum conductivity and durability.

- Insulation: Choose insulated connectors when needed to prevent short circuits and enhance safety.

Adjust Tool Settings

Once you’ve chosen the right connector, making certain your crimping tool is set up properly is the next step for effective electrical work.

Start by checking the adjustable settings on your crimping tool, as these can vary based on the connector type and wire gauge. Most tools have a dial or lever to select the appropriate size. Be sure to consult the tool’s manual for specific adjustments relevant to your connector.

Once you’ve made the necessary changes, do a quick inspection to confirm everything is secure and ready for use. Proper adjustments will enhance performance and reduce the risk of improper crimps.

Take a moment to double-check your settings before moving forward with the crimping process.

Apply Even Pressure

When crimping connectors, applying even pressure is essential for guaranteeing a secure and reliable connection.

You want to avoid any inconsistencies that could lead to electrical failure. Here’s how to achieve that:

- Position the Wire: Place the stripped wire into the connector fully before crimping.

- Align the Tool: Make sure the crimping tool is positioned correctly over the connector.

- Apply Steady Force: Squeeze the handles with a consistent grip, avoiding sudden jerks or shifts.

- Inspect Your Work: Once crimped, check the connection to guarantee it’s tight and secure.

Common Mistakes to Avoid

While it might seem straightforward, crimping can lead to several common mistakes that can jeopardize the integrity of your electrical connections. One major error is using the wrong size of connector, which can prevent a secure fit.

Crimping may seem easy, but common mistakes like using the wrong connector size can compromise your electrical connections.

Also, applying insufficient pressure during crimping can result in a weak connection that may fail under load. Conversely, over-crimping can damage the wire and connector, leading to failure as well.

Not fully inserting the wire into the connector before crimping is another pitfall to avoid; it can compromise the connection.

Finally, neglecting to inspect your work before moving on can lead to undetected issues down the line. Take the time to double-check your crimping to confirm everything’s secure and reliable.

Maintenance and Care for Crimping Tools

To guarantee your crimping tools remain reliable and effective, regular maintenance is essential. By taking care of them, you’ll extend their lifespan and enhance performance.

Here are four key maintenance tips:

- Clean After Use: Wipe the tools with a damp cloth to remove debris and dust, preventing buildup.

- Lubricate Moving Parts: Apply a few drops of machine oil to hinges and joints to ensure smooth operation.

- Inspect Regularly: Check for wear, rust, or damage. Addressing issues early can prevent further deterioration.

- Store Properly: Keep your crimping tools in a dry, safe location, ideally in a toolbox, to protect them from damage and moisture.

Additionally, utilizing proper tools like circuit testers will help enhance safety during your electrical projects. Following these tips will help keep your crimping tools in top condition for your electrical projects.

Safety Tips for Electrical Crimping

Proper maintenance of your crimping tools not only extends their lifespan but also enhances safety during use. Always inspect your tools for any signs of wear or damage before starting a project. This helps prevent accidents caused by faulty equipment.

When crimping, verify you’re working in a dry environment to avoid any risk of electrical shock. Wear safety goggles to protect your eyes from debris, and use gloves to verify a firm grip while preventing cuts or injuries.

Make sure you have a stable work surface to avoid slips and falls. Finally, be cautious of your surroundings – keep bystanders away while you work. Following these tips will help verify a safe crimping experience. Additionally, ensure that your connectors meet industry regulations to guarantee their safety during use.

Beyond Crimping: Other Essential Electrical Tools

While crimping tools are vital for your electrical tasks, you’ll find that other tools are just as important.

Wire strippers and cutters help you prepare your wires, while multimeters let you test connections effectively.

Don’t forget insulation tape, which is essential for ensuring safety and durability in your projects.

Wire Strippers and Cutters

Essential for any electrical work, wire strippers and cutters complement crimping tools by allowing you to manage your wires effectively.

These tools help guarantee clean, precise connections while saving you time during your projects.

Here are four key features to take into account when choosing wire strippers and cutters:

- Gauge Compatibility: Verify the tool fits various wire sizes for versatility.

- Cutting Edge Quality: Look for durable blades to make clean cuts without fraying.

- Ease of Use: Ergonomic designs reduce hand fatigue and increase efficiency.

- Built-in Stops: Some models have adjustable stops for precise stripping lengths.

Incorporating wire strippers and cutters into your toolkit will enhance your electrical work, making it easier and more efficient.

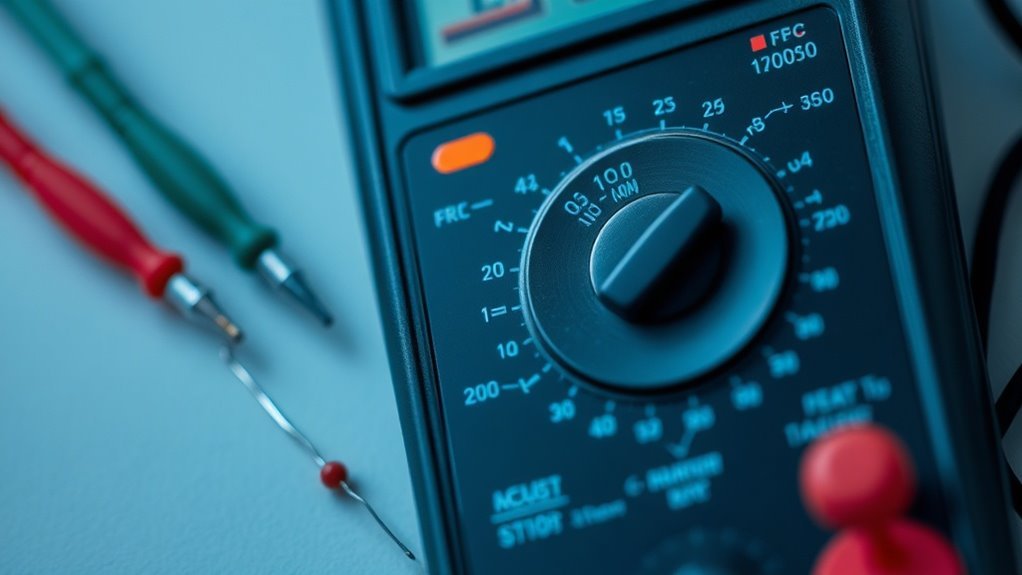

Multimeters for Testing

When it comes to electrical work, having the right tools makes all the difference, and a multimeter is one of those indispensable instruments. It allows you to measure voltage, current, and resistance accurately, ensuring your projects are safe and effective. You’ll find that it quickly becomes a go-to tool for troubleshooting electrical issues.

Here’s a quick comparison of different multimeter types:

| Type | Best For | Price Range |

|---|---|---|

| Digital Multimeter | General use | $20 – $500 |

| Analog Multimeter | Basic measurements | $10 – $100 |

| Clamp Meter | Measuring current easily | $30 – $300 |

Choose the multimeter that fits your needs and watch your electrical skills grow.

Insulation Tape Essentials

Though crimping tools are essential for creating secure electrical connections, they’re just one part of a broader toolkit you’ll need for electrical work.

Insulation tape, for instance, plays a vital role in guaranteeing safety and functionality by protecting wires and connections.

Here are some essentials to take into account when using insulation tape:

- Quality Matters: Always choose high-quality tape that can withstand heat and moisture.

- Width and Thickness: Select the right width to cover connections effectively. Thicker tape provides better insulation.

- Color Codes: Familiarize yourself with color codes to identify wiring better and enhance safety.

- Proper Application: Secure good adhesion by applying the tape evenly and without gaps for maximum protection.

Equipping yourself with insulation tape guarantees reliable and safe electrical work.

Questions

Can I Use Crimping Tools for Non-Electrical Applications?

Yes, you can use crimping tools for non-electrical applications. They’re versatile and work well with various materials, like cables or wires in crafting, plumbing, and automotive. Just guarantee you’re using the right tool for your specific needs.

How Do I Know if My Crimping Tool Is High Quality?

Isn’t it frustrating when tools let you down? To tell if your crimping tool’s high quality, check the material, feel for weight, inspect the consistency of the crimp, and read reviews from other users.

Are There Any Industry Standards for Crimping Connectors?

Yes, there are industry standards for crimping connectors, like those set by the American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE). It’s essential you choose quality connectors that meet these specifications.

What Is the Lifespan of a Typical Crimping Tool?

A crimping tool’s lifespan often stretches from five to ten years, shimmering with longevity if cared for. Regular maintenance, like cleaning and proper storage, can extend its life, ensuring it stays ready for your projects.

Where Can I Purchase Quality Crimping Tools?

You can purchase quality crimping tools at hardware stores, online retailers like Amazon, or specialized electrical supply shops. Just make certain to read reviews to guarantee you’re getting a reliable and durable tool for your needs.

Conclusion

In summary, crimping tools are essential for ensuring secure electrical connections. Did you know that improper crimping can lead to failure rates as high as 50% in certain applications? By choosing the right tool and understanding the features and specifications, you can avoid costly mistakes and increase your project’s reliability. Remember to maintain your tools and follow safety tips to keep both you and your connections safe. Happy crimping!