Electrical Safety Gear: Insulation Principles

Electrical safety gear is essential to protect you from electrical hazards. Effective insulation surrounds conductive components, preventing shocks and energy loss. Common insulating materials like rubber, plastic, and fiberglass serve as barriers against electrical risks. It’s important to guarantee proper insulation thickness based on voltage levels for ideal safety. Inspect your gear regularly for wear and adhere to industry standards. As you explore further, you’ll discover the latest innovations and practices enhancing electrical safety.

Key Takeaways

- Proper electrical insulation is crucial to prevent electric shock and reduce energy loss in safety gear.

- Insulating materials include rubber, plastic, and fiberglass, each offering unique protective properties.

- Insulation thickness must meet industry standards to ensure safety across varying voltage levels.

- Regular testing and certification of safety gear are essential for reliable performance and compliance with safety regulations.

- Innovations like self-healing materials and smart technologies enhance the effectiveness of insulation in electrical safety gear.

Understanding Electrical Insulation

When it relates to electrical safety, understanding electrical insulation is essential, as it helps protect you from shock and other hazards. Insulation is the material that surrounds conductive wires and components, preventing unintended contact and energy loss.

You need to recognize the various types of insulation materials, like rubber, plastic, and ceramics, each offering unique advantages regarding durability and resistance to heat and moisture.

Knowing the importance of proper insulation in electrical systems guarantees that you’re less likely to encounter dangerous situations. Always check for signs of wear and tear on insulation in your appliances and wiring. Additionally, ensuring you use well-insulated tools can significantly enhance overall safety and efficiency.

This simple awareness can make a significant difference in maintaining safety in your home or workplace.

The Role of Insulating Materials in Electrical Safety

Insulating materials play an essential role in guaranteeing electrical safety by acting as barriers that prevent unwanted contact with electricity. They help protect you from electrical shocks and short circuits, which can lead to serious injuries or fatalities. By using these materials, you can ascertain that electrical components remain isolated, minimizing the risk of accidents.

Additionally, insulating materials can reduce the risk of electrical fires by limiting heat buildup caused by faulty wiring or overcurrent situations. When working with or around electrical equipment, it’s vital to rely on proper insulation to keep yourself safe. Regular testing with fuse testers enhances the effectiveness of insulation by ensuring that electrical systems operate safely within their designed parameters.

Types of Insulating Materials Used in Safety Gear

While selecting safety gear, you’ll encounter various insulating materials tailored to meet specific needs in electrical environments. Understanding these materials helps guarantee your protection against electrical hazards.

Here are four commonly used insulating materials in safety gear:

- Rubber – Known for its excellent dielectric properties, rubber is flexible and provides great protection for gloves and footwear.

- Plastic – Lightweight and durable, plastics are often used in various safety tools and equipment.

- Fiberglass – This material is strong, heat-resistant, and used in protective barriers and structural components.

- Nomex – A flame-resistant material, Nomex is frequently found in protective clothing to shield against heat and flames.

Choosing the right insulating material is vital for your safety and comfort on the job. Additionally, being mindful of respiratory protection is crucial to prevent long-term health issues associated with electrical work.

How Insulation Reduces Electrical Risks

Insulation plays a vital role in keeping you safe from electrical hazards. By choosing the right insulation materials, you can effectively minimize the risks associated with electrical exposure. Additionally, understanding comprehensive training on the importance of electrical safety can further enhance your protective measures. Let’s explore why proper insulation is so important and the types of materials that can help protect you.

Importance of Proper Insulation

Proper insulation serves as an essential shield against electrical hazards, reducing the risk of shock or fire in various environments.

Without it, you expose yourself and others to dangerous electrical exposure. Understanding the importance of proper insulation can save lives and property.

Here are some key reasons why insulation is imperative:

- Prevents Shock: Insulation keeps electrical circuits from direct contact with people and conductive surfaces.

- Reduces Fire Risk: High-quality insulation helps contain heat, preventing electrical fires from starting.

- Increases Equipment Lifespan: Proper insulation protects devices from wear and tear caused by environmental factors.

- Enhances Efficiency: Well-insulated wiring optimizes energy flow, reducing power loss and potentially lowering electricity bills.

Types of Insulation Materials

When it comes to electrical safety, knowing the different types of insulation materials can make a significant difference in reducing risks.

Common materials include rubber, PVC, and thermoplastics. Rubber insulation provides excellent flexibility and resistance to abrasion, making it ideal for outdoor applications. PVC is lightweight and offers good moisture resistance, commonly used in wiring for homes and buildings.

Thermoplastics are another great option, known for their durability and high dielectric strength. Each type serves a unique purpose based on the environment and intended use.

Importance of Proper Insulation Thickness

When it comes to electrical safety, proper insulation thickness is essential.

The right thickness not only guarantees effective performance of materials but also greatly impacts your safety. You need to follow insulation thickness recommendations to minimize risks and protect yourself and your equipment.

Insulation Thickness Recommendations

Choosing the right insulation thickness is essential for maintaining electrical safety. If you’re using electrical gear, the thickness of the insulation greatly impacts its protective qualities.

Here are some recommendations to guarantee you’re on the right track:

- Low Voltage Applications: For systems under 1 kV, a minimum thickness of 0.8 mm is suggested.

- Medium Voltage Applications: For voltages between 1 kV and 36 kV, aim for a thickness of 3 mm or more.

- High Voltage Applications: For voltages exceeding 36 kV, consider using insulation at least 5 mm thick.

- Environmental Factors: Always factor in temperature and humidity; additional thickness may be necessary in harsh conditions.

Keep these recommendations in mind to enhance safety and prolong the life of your electrical equipment.

Impact on Safety

Proper insulation thickness plays an essential role in ensuring electrical safety, as it directly influences your protection against shock, electrical faults, and equipment damage.

If the insulation is too thin, it may not provide adequate barriers, putting you at risk of electric shock when you handle wires or devices. Conversely, overly thick insulation can add unnecessary weight and flexibility issues, making it harder to work with your gear.

Finding the right balance is critical for optimal performance and safety. It’s crucial to follow industry standards when choosing insulation thickness, as it can prevent dangerous situations that lead to injury or equipment failure.

Always remember, proper insulation thickness is your first line of defense in electrical safety.

Material Effective Performance

While one might overlook the significance of insulation material, its effectiveness is critical to guaranteeing safety and performance in electrical applications. Choosing the right thickness of insulation isn’t just a matter of preference; it’s essential for ideal functionality.

Here are four key factors to keep in mind regarding proper insulation thickness:

- Voltage Rating: Insulation thickness must align with the voltage capacity to prevent breakdown.

- Environmental Conditions: Varying temperatures and humidity levels necessitate appropriate insulation to maintain performance.

- Mechanical Stress: Insulation needs to withstand physical stress without degrading over time.

- Safety Standards: Compliance with industry standards guarantees that the insulation will protect adequately against electrical hazards.

Testing and Certification Standards for Insulating Gear

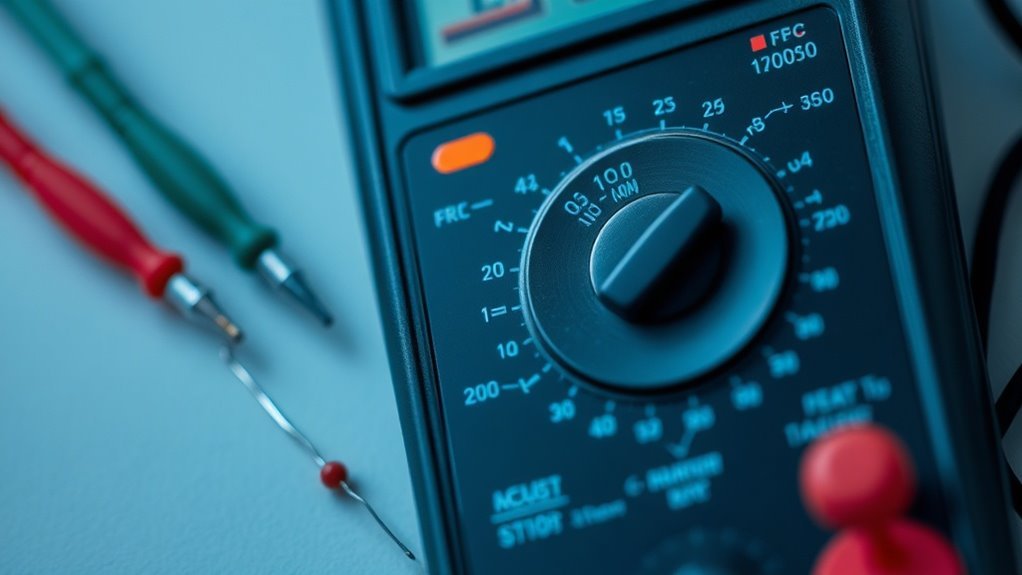

When it comes to electrical safety, understanding the testing and certification standards for insulating gear is essential to guarantee effective protection. Various organizations, like ASTM International and IEC, set rigorous standards that items must meet to assure safety and performance.

For instance, gloves and mats undergo dielectric testing to confirm they can withstand specific voltage levels. Certifications from reputable bodies indicate that the gear has been thoroughly evaluated under controlled conditions.

Always check for marks of compliance, like UL or CE, before purchasing. These standards help you make informed decisions, ultimately assuring that you’re using equipment designed to protect you from electrical hazards. Regular calibration of tools is also important to ensure its reliability and operational efficiency.

Being aware of these certifications is critical for your safety in any electrical work you undertake.

Best Practices for Using Electrical Safety Gear

Understanding testing and certification standards for insulating gear is just the first step in guaranteeing your safety when working with electricity. To maximize protection, follow these best practices when using electrical safety gear:

Maximizing safety with electrical gear starts with understanding standards and following best practices for usage and maintenance.

- Inspect Gear Regularly: Check for any signs of wear, tears, or damage before each use.

- Wear Proper Fit: Confirm your gear fits correctly; loose or tight gear can compromise your safety.

- Follow Manufacturer Guidelines: Always adhere to the recommendations for usage, storage, and maintenance provided by the manufacturer.

- Stay Educated: Regularly participate in training sessions about new safety gear and changes in protocols.

Common Insulation Failures and Their Consequences

Electricity is a powerful force, and insulation failures can lead to serious hazards if not addressed promptly. One common issue is wear and tear on insulation materials, which can result in short circuits and electrical fires.

If you notice frayed wires or melted coverings, don’t ignore them—these signs can indicate imminent failure.

Moisture intrusion is another risk; water can degrade insulation, causing increased conductivity and potential shocks.

Additionally, chemical exposure can weaken insulation, leading to unexpected breakdowns.

Always inspect your gear for these vulnerabilities.

Remember, addressing insulation failures quickly not only protects your equipment but also guarantees your safety and that of those around you.

Don’t underestimate the importance of regular maintenance and vigilance.

Innovations in Electrical Insulation Technology

As technology evolves, so does electrical insulation, making it safer and more efficient for everyone.

You’ll find advancements in materials and the rise of smart insulation technologies are revolutionizing the way we protect against electrical hazards.

These innovations not only enhance safety but also improve overall system performance.

Advancements in Materials

Recent innovations in electrical insulation technology have transformed the safety landscape for electrical workers. These advancements have led to the development of materials that not only enhance safety but also improve durability and efficiency.

When considering insulation materials, you’ll find some key advancements include:

- Nanomaterials: These offer superior heat resistance and mechanical properties, making them ideal for high-performance insulation.

- Polymer blends: Combining various polymers results in enhanced flexibility and resistance to environmental factors.

- Bio-based materials: Environmentally friendly options are emerging, providing safe alternatives without sacrificing performance.

- Advanced coatings: New coatings provide added protection against moisture and chemical exposure, increasing the lifespan of insulation.

Smart Insulation Technologies

While traditional insulation materials have considerably improved, smart insulation technologies are taking safety and efficiency to the next level. These next-gen materials can monitor electrical systems in real-time, providing data that helps prevent failures. They adjust insulation properties dynamically, responding to temperature changes and electrical loads. Imagine how these advancements can protect you and your equipment from potential hazards.

Here’s a snapshot of some smart insulation technologies:

| Technology | Features | Benefits |

|---|---|---|

| Self-healing Insulation | Repairs itself after damage | Increased lifespan |

| Nanotechnology | Enhanced strength and flexibility | Lightweight, durable insulation |

| Phase Change Materials | Regulates temperature | Energy efficiency |

| Conductive Polymers | Active monitoring capabilities | Early failure detection |

| Smart Coatings | Adaptive properties | Versatile applications |

The Future of Electrical Safety and Insulation Techniques

The future of electrical safety hinges on the innovation of insulation techniques that not only enhance protection but also adapt to emerging technologies.

As we move forward, you’ll likely see significant advancements in materials and methods that guarantee safer environments.

Here are some key trends to watch for:

- Smart Insulation Materials: Self-regulating materials that adjust based on temperature and electric load.

- Nanotechnology: Utilization of nano-coatings for improved durability and insulation effectiveness.

- Biodegradable Insulators: Eco-friendly materials that minimize environmental impact while maintaining safety standards.

- Wearable Safety Gear: Integrating safety devices into clothing for real-time monitoring and alerts.

Additionally, developments in electrical connectors will play a vital role in enhancing the overall safety and reliability of electrical systems.

These innovations promise a safer future in electrical applications, making it imperative to stay informed about these developments.

Questions

How Do I Choose the Right Electrical Safety Gear for Specific Tasks?

To choose the right electrical safety gear, assess your task’s voltage and potential hazards. Look for gear that meets industry standards, fits properly, and offers adequate insulation and protection for your specific work environment.

What Are the Costs Associated With High-Quality Insulating Materials?

Choosing high-quality insulating materials can be pricey, typically ranging from $1 to $10 per square foot, depending on specifications. Don’t forget to factor in installation costs; they could add a few bucks to your budget too!

Can Insulation Materials Degrade Over Time, and How Can I Check?

Yes, insulation materials can degrade over time. You can check for signs like cracks, brittleness, or discoloration. Regular inspections and replacing worn-out insulation will help guarantee your safety and equipment efficiency.

Are There Environmental Impacts of Disposing of Old Insulating Gear?

Just like discarded treasures, old insulating gear can harm the environment. When you improperly dispose of it, toxic materials can leach into soil and water, affecting ecosystems. Always recycle or dispose of them responsibly.

What Personal Protective Equipment Complements Electrical Safety Gear Effectively?

To complement electrical safety gear effectively, you should use hard hats, safety goggles, dielectric gloves, and proper footwear. These items help protect you from electrical hazards, ensuring your safety while working in potentially dangerous environments.

Conclusion

To sum up, while you might think you can safely skip electrical safety gear because “that’ll never happen to me,” remember that insulation isn’t just for cozy feelings on winter nights. It’s your first line of defense against becoming a human conductor! So, when you suit up, just imagine you’re a superhero warding off shocking experiences. After all, no one dreams of a career in static cling or becoming a shocking sensation in the emergency room. Stay safe, folks!