Grounding: Essential Safety Knowledge for DIY Electricians

Grounding is vital for DIY electricians. It prevents dangerous voltage levels that could lead to electric shocks or fires. Understanding the different grounding systems, like solidly or impedance grounded systems, is key. When grounding outlets, always use a dedicated wire and regularly test for proper connections. Watch out for common mistakes, like poor wire connections. Ensuring proper grounding and maintenance can greatly enhance safety in your projects. There’s much more essential knowledge to explore on this topic.

Key Takeaways

- Grounding prevents electrical shocks and fires by directing excess current safely away from people and equipment during faults.

- Use three-prong grounded outlets and ensure they connect to a dedicated grounding wire for proper safety.

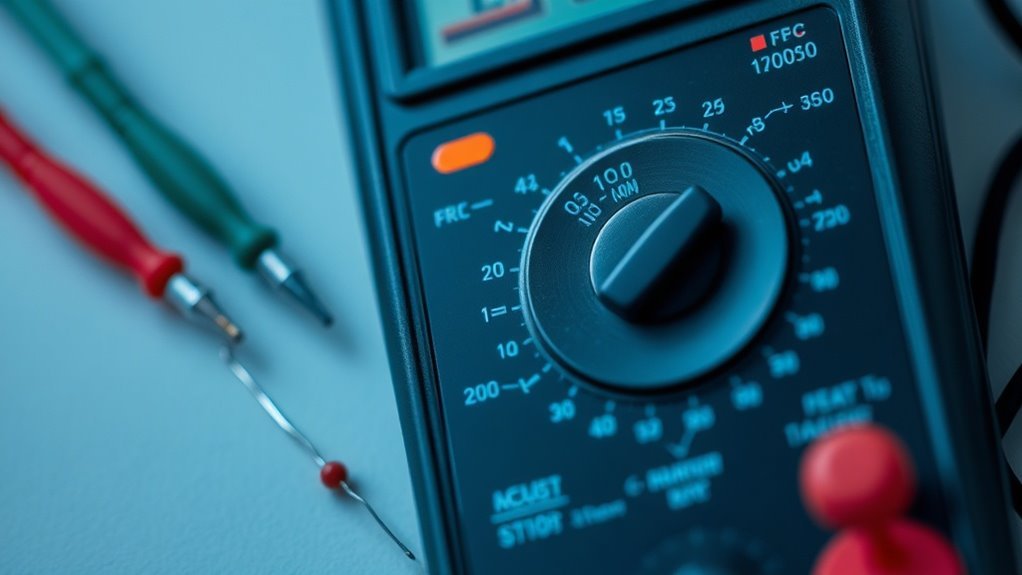

- Regularly test grounding systems with a multimeter to check for continuity and adequate resistance levels, ideally below 25 ohms.

- Avoid common grounding mistakes, such as inadequate connections and using incorrectly sized wire, to maintain system reliability.

- Document all testing and maintenance activities for safety compliance and future reference in grounding practices.

What Is Grounding and Why Is It Important?

Grounding is a fundamental safety measure in electrical systems, acting as a protective pathway for excess electricity. It prevents dangerous voltage levels that could cause electrical shock or fires, guaranteeing your safety and the safety of your home.

When electrical faults occur, grounding directs excess current away from you and your equipment, minimizing damage. As a DIY electrician, understanding grounding’s importance is essential. Without proper grounding, your projects can become hazardous, increasing the risk of equipment failure or serious injury.

It’s not just a technical requirement; it’s a critical practice for safe electrical work. So, always make sure your electrical systems are grounded correctly, providing peace of mind and promoting a safe environment while you tackle your DIY projects.

The Different Types of Grounding Systems

When you’re working with electrical systems, understanding the different types of grounding is essential.

There are system grounding types that protect the overall setup, and equipment grounding basics that safeguard individual devices.

Let’s explore how each of these grounding methods plays a critical role in electrical safety. Additionally, using tools like circuit testers can help ensure that your grounding systems are functioning correctly.

System Grounding Types

There are several grounding system types that every DIY electrician should know. The first is a solidly grounded system, where all neutral conductors connect directly to the ground. This type effectively eliminates potential voltage issues but requires careful considerations.

Next is the impedance grounded system, which uses a resistor or reactor for grounding. It limits fault current, helping protect equipment.

Then you have a ungrounded system, often used in specific applications where continuity is crucial. It allows continued operation during a single fault but can create hazardous conditions.

Finally, a reduced-voltage grounding system is less common, designed to minimize touch voltages. Understanding these systems helps you choose the right grounding method for your electrical setup.

Equipment Grounding Basics

Understanding equipment grounding basics is essential for any DIY electrician looking to guarantee safety and reliability in their projects.

There are several grounding systems you should be aware of. The most common is the equipment grounding conductor (EGC) that connects your tools and fixtures to ground. This prevents electrical faults from causing shocks.

Another type is the grounding electrode system, which connects your electrical system to the earth. This helps dissipate electrical surges and lightning strikes.

Finally, isolated ground systems can be used for sensitive equipment, reducing electrical noise and interference.

Knowing these grounding types will guarantee your projects are both safe and efficient, so always prioritize proper grounding techniques.

Grounding Electrode Systems: An Overview

Grounding electrode systems are essential for ensuring electrical safety in your home or workshop, as they provide a pathway for fault currents to safely dissipate into the ground.

These systems usually consist of grounding rods, plates, or other metal components buried in the earth. When something goes wrong with your electrical system, a grounding electrode helps redirect dangerous currents away from people and sensitive equipment.

It’s important that your grounding electrode system is properly installed and maintained to avoid issues. Local codes often dictate installation practices, so check those before you start.

Knowing the basics of grounding electrode systems will help you understand their critical role in keeping your DIY projects safe and compliant with regulations.

How to Properly Ground Electrical Outlets

To properly ground electrical outlets, you’ll first need to understand the basics of grounding and why it’s essential for safety.

Next, you’ll connect the grounding wire correctly to guarantee a secure connection.

Finally, testing your outlet’s grounding helps confirm that everything’s functioning as it should be.

Understanding Grounding Basics

Electrical safety hinges on proper grounding, which is vital for protecting you and your devices from shock and damage. Understanding how to ground your electrical outlets is imperative for a safe DIY project.

Here are some key grounding basics:

- Grounding Wire: Confirm a dedicated grounding wire connects to your outlet, typically green or bare.

- Grounding System: Familiarize yourself with your home’s grounding system, which usually connects to a grounding rod or metal water pipe.

- Receptacle Type: Use a grounded outlet (three-prong) for electrical devices requiring grounding.

- Regular Testing: Periodically test outlets with a meter or receptacle tester to verify proper grounding.

Grounding Wire Connections

While it might seem straightforward, properly connecting grounding wires is essential to ensuring your outlets function safely.

Begin by turning off the circuit breaker to avoid any electrical shock. Remove your outlet cover and unscrew the outlet from the box.

You’ll find a green grounding screw; this is where you’ll attach the grounding wire. Strip about 3/4 inch of insulation from the grounding wire, then loop it around the ground screw, ensuring it’s tight and secure. Make sure the copper wire is in good condition; if it’s frayed, replace it.

After that, reattach the outlet and cover. Don’t forget to turn the circuit breaker back on! A correctly grounded outlet not only protects your devices but also keeps you safe.

Testing Outlet Grounding

Testing outlet grounding is essential for guaranteeing safety and functionality in your home. Properly grounded outlets can prevent electrical shocks and keep your devices working correctly.

Here’s how to test your outlets:

- Turn Off Power: Safety first! Switch off the circuit breaker or remove the fuse for the outlet you’re testing.

- Use a Multimeter: Set your multimeter to the AC voltage setting and insert the probes into the outlet slots.

- Check the Readings: A reading close to zero indicates improper grounding. Ideally, you want a reading of around 120 volts.

- Ground Wire Check: If there’s no ground, inspect the wiring to verify the ground wire is connected to the outlet and your electrical panel.

Regular testing can keep your home safe!

Common Grounding Mistakes to Avoid

When you’re diving into DIY electrical projects, it’s easy to overlook critical grounding details that can lead to serious safety issues.

One common mistake isn’t properly connecting the ground wire; make sure it’s securely attached to both the outlet and the grounding bar.

Another error is using a ground wire that’s too thin; always follow local codes regarding wire gauge for safety.

Don’t forget to check for ground continuity—just assuming it’s in place isn’t enough.

Also, avoid grounding to water pipes, as they can corrode and create weak connections.

Finally, neglecting to label your ground wires may cause confusion in future projects.

Testing and Maintenance of Grounding Systems

Guaranteeing your grounding system is functioning properly is essential to maintaining electrical safety in your home.

Regular testing and maintenance can help prevent potential hazards. Here’s how you can keep your grounding system in check:

- Visual Inspection: Regularly check for corrosion, loose connections, or damage to grounding wires.

- Continuity Test: Use a multimeter to guarantee there’s a proper conductive path from the equipment ground to the ground rod.

- Resistance Measurement: Measure the ground resistance with a ground resistance tester; ideally, it should be 25 ohms or less.

- Documentation: Keep records of tests and maintenance for reference; this helps identify any recurring issues.

Stay proactive, and your grounding system will provide the safety you need.

Questions

What Tools Do I Need for Grounding Electrical Systems?

You’ll need a multimeter to check voltage, grounding rods, clamps, copper wire, a hammer for driving rods, and safety gear like gloves and goggles. Having these tools helps guarantee your grounding system’s effectiveness and safety.

Can I Use a Water Pipe as a Grounding Electrode?

Picture a sturdy oak tree anchoring deep roots in the earth. You can use a water pipe as a grounding electrode, but it’s essential to guarantee it’s properly bonded and meets local code requirements for safety.

How Often Should Grounding Systems Be Inspected?

You should inspect grounding systems at least once a year. However, if you notice any changes, like corrosion or damage, it’s wise to check more frequently. Keeping it safe guarantees reliable electrical performance.

What Are the Signs of a Faulty Grounding System?

You can spot a faulty grounding system by observing flickering lights, frequent circuit breaker trips, a tingling sensation when touching appliances, or rusted grounding rods. Always address these issues promptly to avoid safety hazards.

Is Grounding Necessary for Low-Voltage Systems?

Yes, grounding’s necessary for low-voltage systems. It reduces the risk of electrical shock and equipment damage, ensuring safety and operational efficiency. Ignoring it could lead to hazards that you definitely want to avoid.

Conclusion

In summary, understanding grounding isn’t just for professionals; it’s crucial for DIY electricians like you. While you might think grounding is complicated, it’s quite manageable with the right knowledge and approach. By ensuring your electrical systems are properly grounded, you’re not only protecting your home but also enhancing your safety and preventing costly damage. So, get hands-on with your projects and embrace grounding as an important step in your DIY journey.