Identifying Wire Gauges and Their Applications

Identifying wire gauges is essential for any electrical project. It’s important to know that lower gauge numbers indicate thicker wires, which handle more current for heavy-duty needs, while higher gauges are better for smaller, delicate applications. Each wire gauge has specific applications, from automotive wiring to residential circuits and electronics. Understanding these differences guarantees safety and efficiency. If you want to learn more about choosing the right wire gauge for your projects, there’s plenty more to explore.

Key Takeaways

- Wire gauge indicates the diameter of the wire, with lower numbers indicating thicker wires suitable for high-current applications.

- Low gauge wires (10-12 AWG) are ideal for automotive and industrial applications due to their high current capacity and low resistance.

- Medium gauge wires (14-10 AWG) are commonly used in residential settings for lighting circuits and powering typical home appliances.

- High gauge wires (16 and above) are suited for electronics and telecommunications, ensuring minimal signal loss in compact devices like smartphones and computers.

- Proper wire gauge selection is critical for safety, efficiency, and compliance with electrical codes, preventing overheating and ensuring secure connections.

Understanding Wire Gauge Measurement

Understanding wire gauge measurement can seem intimidating at first, but once you grasp the basics, it’s quite straightforward.

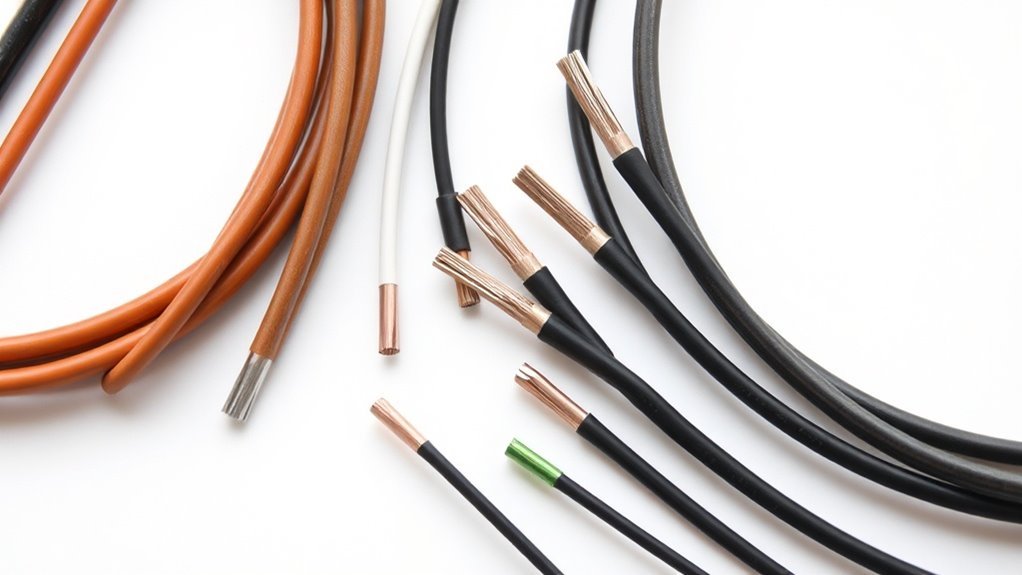

Wire gauge refers to the diameter of the wire, and it’s essential for determining its current-carrying capacity, flexibility, and resistance. Generally, a lower gauge number indicates a thicker wire, while a higher number signifies a thinner one. For instance, a 10-gauge wire is thicker than a 20-gauge wire.

Remember, thicker wires can handle more electricity, making them suitable for heavy-duty applications. Knowing the right gauge guarantees safety and efficiency in electrical projects.

Standard Wire Gauge Systems

There are several standard wire gauge systems used across different industries, each with its own specific measurements and applications.

The American Wire Gauge (AWG) is perhaps the most well-known, common in electrical work. It uses a numerical scale where a lower number signifies a thicker wire.

Then there’s the Imperial System, primarily used in some European countries, which also employs a similar principle.

The Metric Wire Gauge system, on the other hand, measures wire diameter in millimeters and is often used in local applications and smaller devices.

Additionally, you might encounter the Standard Wire Gauge (SWG) system, used mainly in the UK.

Knowing these systems helps guarantee you select the right wire for your specific needs.

Characteristics of Different Wire Gauges

Different wire gauges come with unique characteristics that affect their performance in various applications. For instance, smaller gauge wires, like 16 or 18, offer higher resistance and can handle less current, making them suitable for delicate electronic circuits.

Smaller gauge wires, such as 16 or 18, are ideal for delicate circuits due to their higher resistance and lower current capacity.

On the other hand, larger gauge wires, such as 10 or 12, have lower resistance and are better at carrying more current, which is ideal for heavy-duty tasks.

The thickness of the wire also impacts flexibility; thinner wires are easier to bend and maneuver in tight spaces. Additionally, insulation types can vary, affecting durability and heat resistance.

Knowing these characteristics helps you select the right wire gauge based on your project’s specific needs, ensuring safety and efficiency.

Common Applications for Low Gauge Wires

Low gauge wires play a vital role in various applications, especially in automotive wiring systems and high-power electrical circuits.

You’ll find them essential in heavy-duty appliances where reliability and power handling are important.

Understanding these common uses can help you select the right wire for your needs.

Automotive Wiring Systems

When you think about automotive wiring systems, the importance of low gauge wires becomes clear, as they play a crucial role in handling high currents essential for various components.

In vehicles, these wires typically connect batteries to starters, alternators, and fuel pumps. Their lower resistance allows for efficient power delivery, ensuring that critical systems operate smoothly.

Low gauge wires also help with the functioning of headlights, taillights, and other electrical accessories that demand a lot of energy.

Using the appropriate gauge prevents overheating and potential hazards, keeping you safe on the road.

High-Power Electrical Circuits

High-power electrical circuits are vital in a variety of applications, and using the right gauge wires can make all the difference.

When you’re working with high-current systems like industrial machinery, electric vehicles, or solar power installations, you’ll often need low gauge wires to handle the increased load. These wires minimize resistance, reduce heat buildup, and guarantee safety by preventing overheating.

You might also find low gauge wires in power distribution panels where reliability is key.

Remember, using inappropriate gauges can lead to failures, fires, or inefficiencies. Always assess your specific requirements, and don’t hesitate to consult an expert if you’re unsure.

Choosing the right wire gauge is essential in maximizing performance and safety for your high-power electrical circuits.

Heavy-Duty Appliances Usage

Heavy-duty appliances often require robust wiring to guarantee peak performance and safety.

When you’re dealing with high-current devices like refrigerators, air conditioners, and electric ranges, using lower gauge wires is essential. These wires can handle increased amperage without overheating, which helps prevent electrical failures and fire hazards.

For instance, a 10-gauge wire is commonly used for kitchen appliances and large power tools, ensuring they operate efficiently. You’ll want to make sure to match the wire gauge with the appliance’s specific electrical demands.

Also, using the correct gauge not only preserves the integrity of the appliance but can also improve your home’s overall electrical system reliability.

Always prioritize safety and consult professional guidelines when wiring heavy-duty appliances.

Uses of Medium Gauge Wires in Electrical Projects

When working on electrical projects, medium gauge wires are often your go-to choice for a variety of applications.

You’ll find that these wires strike a balance between flexibility and strength, making them suitable for many tasks.

Understanding their common uses and benefits will help you choose the right wire sizing standards for your projects.

Common Applications

Medium gauge wires play an essential role in a variety of electrical projects, especially in residential and commercial settings. You’ll often find these wires being used for lighting circuits and powering outlets, making them vital for everyday electrical needs.

Medium gauge wires are also perfect for appliances like refrigerators, washers, and dryers, where reliable and safe power transmission is a must. Additionally, they’re great for running audio and video systems, helping to deliver quality signals without interference.

If you’re hooking up data cables or communication systems, medium gauge wires are up to the task, providing a solid connection. Overall, they’re a versatile choice that meets a range of project demands, ensuring efficiency and safety in your electrical installations.

Wire Sizing Standards

In many electrical projects, understanding wire sizing standards is essential for ensuring safety and efficiency. Medium gauge wires, often ranging from 14 to 10 AWG, are commonly used for various applications like lighting, receptacles, and small motor connections.

Here’s a quick reference table for common wire sizes and their uses:

| Wire Gauge (AWG) | Typical Use | Max Amperage |

|---|---|---|

| 14 | Lighting circuits | 15 A |

| 12 | General outlet wiring | 20 A |

| 10 | Heavy appliances, smaller motors | 30 A |

Choosing the right gauge not only affects performance but also plays a critical role in preventing potential hazards in your electrical work.

Benefits of Medium Gauge

Understanding the benefits of medium gauge wires is essential for anyone involved in electrical projects, as these wires strike a balance between flexibility and capacity.

They’re versatile and suitable for a variety of applications, making them a reliable choice. Here are three key advantages:

- Flexibility: Medium gauge wires are easier to work with and can be maneuvered around corners and tight spaces without breaking or kinking.

- Current Capacity: They efficiently transmit moderate levels of electrical current, making them ideal for residential wiring and lower-demand systems.

- Cost-Effectiveness: Using medium gauge wires can reduce costs without sacrificing performance, especially in larger projects where savings add up.

Incorporating medium gauge wires in your projects can enhance both safety and functionality.

Applications of High Gauge Wires

Although high gauge wires may seem delicate, they play an essential role in various applications, particularly in electronics and telecommunications.

You’ll often find these wires in devices like smartphones, computers, and audio equipment, where their fine gauge allows for intricate connections without taking up too much space. High gauge wires are also vital in high-frequency applications, as they minimize signal loss and interference, leading to clearer audio and faster data transmission.

Additionally, they’re utilized in light applications, such as LED lighting systems, where lightweight and flexible wiring is necessary. In circuit boards, they enable compact designs, making it easier to fit advanced technology into smaller components, showcasing their importance in today’s tech-driven world.

Factors to Consider When Choosing Wire Gauge

When selecting the right wire gauge for your project, you should consider several critical factors to guarantee maximum performance and safety.

Here are three essential elements to keep in mind:

- Current Capacity: Each wire gauge has a specific current-carrying capacity. Determine your project’s power needs to avoid overheating issues.

- Voltage Drop: For longer runs, a thicker gauge can reduce voltage drop in the wire. Calculate the distance and assess how it affects your system’s efficiency.

- Flexibility and Environment: Depending on where you’ll be using the wire, consider its flexibility and resistance to environmental factors like moisture or temperature.

Safety Implications of Using Incorrect Wire Gauge

Choosing the wrong wire gauge can lead to serious safety risks that you can’t afford to ignore.

If the wire’s gauge is too small for the current it carries, overheating can occur, causing insulation to melt or even starting a fire. Likewise, if the gauge is too large, you could experience poor connections, which can lead to electrical arcing and equipment failure.

It’s essential to understand that using improper wiring compromises not only your equipment but also your safety. Over time, faulty wiring can create a dangerous environment, increasing risks of electrocution or significant property damage. To enhance safety, ensure you utilize essential tools like circuit testers that help verify the integrity of your electrical systems.

To avoid these hazards, always make certain you’re using the right wire gauge for your specific application, protecting yourself and your belongings.

Tips for Properly Wiring Electrical Projects

Here are three key points to evaluate:

- Choose the Right Wire Gauge: Always match the wire gauge to the project’s voltage and current requirements, securing safety and efficiency.

- Secure Connections: Use the right connectors and make sure all connections are tight. Loose wires can cause shorts or sparks.

- Follow Local Codes: Familiarize yourself with local electrical codes and regulations. Compliance is imperative for safety and inspections. Additionally, understanding the importance of proper grounding techniques can prevent electrical hazards and enhance the overall safety of your projects.

Questions

How Do I Measure Wire Gauge Accurately at Home?

To measure wire gauge accurately at home, use a wire gauge tool or caliper. Alternatively, you can compare the wire with a standard gauge chart online, ensuring you’re measuring the diameter correctly.

Can I Combine Different Wire Gauges in One Project?

Yes, you can combine different wire gauges in one project, but keep in mind that 75% of electrical fires stem from improper wiring. Make certain to understand each gauge’s limitations to guarantee safety and effectiveness.

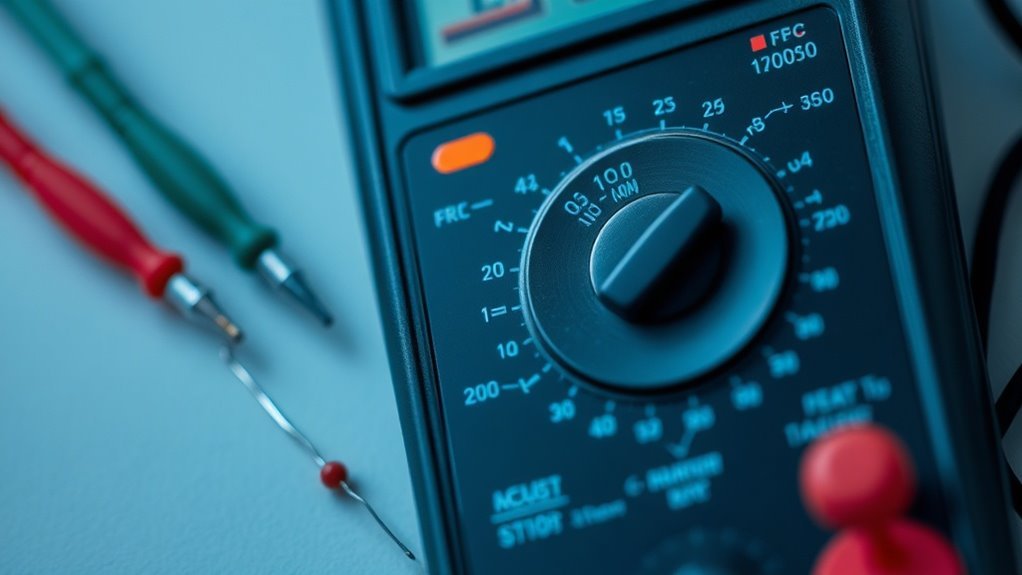

What Tools Are Needed for Wire Gauge Identification?

You’ll need a wire gauge tool or caliper for accurate measurements, along with a digital multimeter for checking electrical properties. Having a ruler can also help in determining other dimensions related to your project.

How Does Temperature Affect Wire Gauge Performance?

Temperature can considerably affect wire gauge performance. If it becomes too hot, resistance increases, leading to overheating and potential failure. Conversely, lower temperatures can enhance conductivity, but may also cause materials to become brittle. It is crucial to monitor conditions.

What Are the Signs of Using Incorrect Wire Gauge?

You’ll notice overheating, increased resistance, and potential electrical fires when using an incorrect wire gauge. Additionally, devices may underperform or malfunction, leading to costly repairs and safety hazards. Always confirm you’ve got the right gauge.

Conclusion

In summary, understanding wire gauges is essential for any electrical project. You might think it’s too complicated, but knowing the right gauge can save you time and money. Low, medium, and high gauge wires all have specific roles that, when matched correctly to your needs, guarantee safety and efficiency. By choosing the right gauge and following safety guidelines, you’ll not only enhance your project’s performance but also feel more confident in your wiring skills. Happy wiring!