Importance of Calibration in Electrical Tools

Calibration is essential for your electrical tools. It guarantees accuracy, preventing costly mistakes and safety hazards. When your tools are calibrated, they measure voltage, current, and resistance accurately, which protects against equipment damage and electrical shocks. Regular calibration keeps your tools functioning within specifications, enhancing project reliability. If you’ve noticed inconsistent readings or physical damage, it’s a sign your tools need recalibration. There’s much more to explore about best practices and future trends in calibration technology.

Key Takeaways

- Calibration ensures accurate measurements, preventing costly errors and enhancing safety in electrical tasks.

- Regular calibration maintains tools within operational specifications, promoting reliable project outcomes.

- Inconsistent readings or physical damage in tools signal the need for recalibration to ensure precision.

- Failure to calibrate can lead to significant financial losses due to operational downtime and material waste.

- Emerging technologies like IoT and AI are shaping the future of efficient calibration practices for electrical tools.

What Is Calibration and Why Is It Necessary?

Calibration is like fine-tuning a musical instrument; it guarantees that your electrical tools perform accurately and reliably.

Calibration fine-tunes your tools for precise performance, ensuring accuracy and reliability in every task.

Basically, calibration is the process of adjusting your tools to measure their output against a known standard. You can think of it as a safeguard against errors that could lead to faulty readings or, worse, unsafe conditions.

Why’s it necessary? Well, without proper calibration, you risk using tools that provide inaccurate results, which can result in costly mistakes and potential safety hazards. Regular calibration guarantees your tools remain within specifications and function effectively over time. Calibration is crucial for ensuring accurate voltage, current, and resistance measurements, which ultimately aids in successful diagnostics.

It’s not just about performance; it’s about maintaining safety and efficiency in your work. So, make calibration a routine part of your tool maintenance strategy.

Tools Commonly Requiring Calibration

Here are three common tools that often require calibration:

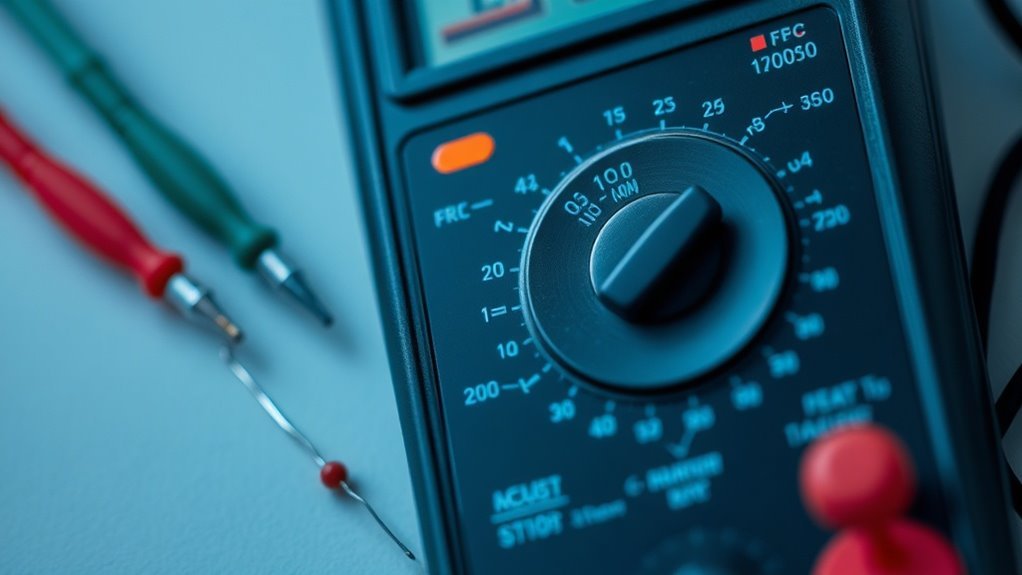

- Multimeters: These devices measure voltage, current, and resistance. Regular calibration confirms accurate readings for effective troubleshooting.

- Oscilloscopes: Precision in waveform analysis is critical. Calibration helps maintain signal integrity and accurate measurements.

- Power analyzers: Used for evaluating electrical power quality, these tools need calibration to verify and optimize performance. Regular checks help ensure continuity testing produces reliable results and maintains circuit integrity.

The Impact of Calibration on Tool Accuracy

Accurate measurements are essential in electrical work, as even slight deviations can lead to costly errors. Calibration guarantees your tools provide precise readings, helping you maintain accuracy in your projects. When your tools are well-calibrated, you reduce the risk of failures or malfunctions which can compromise your work quality.

Here’s a quick overview of how calibration impacts tool accuracy:

| Calibration Frequency | Impact on Accuracy |

|---|---|

| Daily | Minor drift, minimal impact |

| Weekly | Noticeable inaccuracies |

| Monthly | Significant errors |

Safety Risks of Using Uncalibrated Tools

Using uncalibrated tools can expose you to serious safety risks, as inaccurate measurements might lead to hazardous situations. When you’re working with electrical tools, precision is vital.

Using uncalibrated tools poses significant safety risks; accurate measurements are essential, especially with electrical equipment.

Here are three major risks you should be aware of:

- Electrical Shock: If your tools aren’t calibrated, you could misjudge voltage levels, increasing the chance of a shock.

- Equipment Damage: Unreliable measurements might result in overloading or damaging expensive equipment, leading to costly repairs or replacements.

- Inaccurate Readings: Miscalculating measurements can lead to faulty installations, putting both your work and your safety at risk.

To safeguard yourself and your projects, always confirm your tools are properly calibrated. Regular testing and maintenance using fuse testers can also enhance your safety. Safety should never be compromised!

Enhancing Efficiency Through Regular Calibration

Regular calibration can greatly boost the accuracy of your electrical tools, ensuring precise measurements and better results in your projects.

Not only does this enhance performance, but it also contributes to extending the lifespan of your tools, saving you money in the long run.

Improved Accuracy Rates

Calibration is the backbone of precision in electrical tools, ensuring they perform at their best. When you regularly calibrate your tools, you’ll notice significant improvements in accuracy rates, which can enhance your overall efficiency.

Here are three key advantages of maintaining accurate calibrations:

- Consistent Performance: You’ll achieve repeatable results in your projects, reducing errors and rework.

- Better Measurements: Accurate readings lead to informed decisions, minimizing the risk of costly mistakes.

- Increased Confidence: Knowing your tools are calibrated boosts your trust in their reliability, making you more efficient in your work.

Extended Tool Lifespan

Extending the lifespan of your electrical tools can greatly enhance your efficiency and cost-effectiveness. When you regularly calibrate your tools, you’re ensuring they operate at their best, reducing the risk of wear and tear.

Proper calibration helps to identify any potential issues early, preventing more significant problems down the line. You’ll notice that well-calibrated tools not only last longer but also perform more consistently, saving you time and resources.

Plus, the need for replacements decreases, lowering your overall operational costs. By investing a little time in regular calibration, you’re maximizing the performance of your tools and getting the most out of your equipment.

This investment in maintenance leads to a more efficient workflow and longer-lasting tools.

The Calibration Process Explained

Calibration guarantees your electrical tools function accurately and safely. You’ll want to understand the steps involved in the calibration process and the tools that make it possible. Let’s break down what calibration really means and how you can effectively implement it. Proper insulation in electrical tools is essential for ensuring safety during calibration, as it helps minimize the risk of electrical shock while working with these devices.

Definition of Calibration

Understanding calibration is essential for guaranteeing the accuracy and reliability of electrical tools.

Simply put, calibration is the process of comparing your tool’s measurements against a standard. It helps you ascertain that your equipment delivers precise results.

Here are three key aspects of calibration:

- Accuracy: Calibration checks that your tool measures correctly within specified limits.

- Reliability: Regular calibration guarantees your readings remain consistent over time, reducing the likelihood of errors.

- Verification: It acts as a confirmation that your instrument is functioning properly, giving you confidence in your measurements.

Steps in Calibration

Accurate measurements don’t just happen; they require a systematic approach to calibration. First, identify the tool you need to calibrate. Next, gather the necessary standards, which serve as references.

Then, verify your work environment is stable and free from interference. Begin the calibration by taking initial measurements and comparing them to the standards. If discrepancies arise, adjust the tool accordingly and record the changes.

After making adjustments, retest to confirm accuracy. Finally, document all findings and adjustments, noting the date and conditions under which the calibration was performed.

Regularly repeating these steps will help maintain accuracy and verify your electrical tools remain reliable over time, preventing future measuring errors. Proper calibration truly matters for consistent results.

Tools for Calibration

A reliable set of calibration tools is essential for achieving precise measurements in any electrical project.

You can’t underestimate the importance of using the right tools to guarantee your equipment functions correctly.

Here are three essential calibration tools you’ll want to have:

- Multimeter – This versatile instrument measures voltage, current, and resistance, making it indispensable for diagnostics and calibration.

- Calibrated Resistors – These allow you to test and calibrate your multimeter or other equipment against known values for accuracy.

- Temperature Sensor – Essential for calibrating devices sensitive to temperature variations, guaranteeing you get accurate readings in various environments.

Using these tools will enhance your calibration process, giving you confidence in your measurements and results.

Frequency of Calibration: Best Practices

While it may seem like a minor detail, knowing how often to calibrate your electrical tools can greatly impact their performance and your overall safety.

As a general rule, you should calibrate tools at least once a year, but frequency can vary based on usage and environment. If you’re using your tools daily or in harsh conditions, quarterly checks might be necessary.

For specialized tools, like oscilloscopes or multimeters, follow the manufacturer’s recommendations. Always keep a log of your calibration dates to track when it’s time for the next one.

Regular calibration not only guarantees accuracy but also extends the lifespan of your tools, ultimately saving you time and money in the long run. Stay proactive for best results!

Signs Your Tools Need Calibration

How can you tell when your electrical tools need calibration? It’s vital to keep an eye out for signs that indicate your tools might be off.

Here are three key indicators to watch for:

- Inconsistent readings: If you’re noticing that your tools give different measurements for the same task, it’s a clear sign they might need recalibration.

- Physical damage: Any dents, cracks, or wear on your tools can affect their accuracy. Inspect them regularly for such issues.

- Recurrent errors: If you find yourself repeatedly correcting or compensating for inaccuracies, it’s time to calibrate your tools to guarantee reliable performance.

Regular attention to these signs can help maintain the reliability of your equipment and the quality of your work.

Cost Implications of Neglecting Calibration

If you overlook calibration, you might face serious financial risks from inaccuracies in your work.

Not only could this lead to costly errors, but you may also find yourself dealing with increased maintenance expenses as tools wear out faster.

It’s vital to understand how neglecting calibration can impact your bottom line. Moreover, inaccuracies can stem from not adhering to Ohm’s Law, which could further exacerbate the reliability of your electrical measurements.

Financial Risks of Inaccuracy

Neglecting calibration can lead to significant financial risks, as inaccurate measurements often result in costly mistakes. When you’re not calibrating your electrical tools, you might face setbacks that hit your wallet.

Here are a few financial implications to contemplate:

- Operational Downtime: If tools malfunction due to inaccuracies, your project could be delayed, costing you time and money.

- Material Waste: Incorrect measurements can lead to buying excess materials or scrapping products, resulting in wasted resources.

- Rework Costs: Mistakes from uncalibrated tools often necessitate redoing work, which not only takes time but also adds to labor costs.

Ultimately, investing in regular calibration can save you from these financial pitfalls and guarantee your operations run smoothly.

Increased Maintenance Expenses

Inaccurate calibration not only leads to financial risks but also drives up maintenance expenses. When your electrical tools aren’t calibrated properly, they can cause premature wear and tear on components, leading to breakdowns and the need for more frequent repairs.

You’ll quickly find that the costs of these fixes can add up, impacting your budget. Furthermore, using poorly calibrated tools can result in inefficiencies that require additional labor and resources, further inflating your expenses.

Regular calibration helps maintain tool precision, reducing the likelihood of malfunctions. Investing in calibration might seem like an added cost, but it’s a smart way to save money in the long run by preventing unexpected maintenance bills and ensuring ideal tool performance.

Future Trends in Tool Calibration Technology

The landscape of tool calibration technology is rapidly evolving, driven by advancements in automation and digital integration.

You’ll find that future trends will greatly enhance the accuracy and efficiency of calibrating electrical tools.

Here are three key trends to keep an eye on:

- Remote Calibration Monitoring: With IoT integration, you can monitor tool performance and calibration status in real-time from anywhere.

- AI-Driven Calibration Systems: Machine learning algorithms will predict calibration needs, minimizing downtime and optimizing performance.

- Portable Calibration Devices: Compact, battery-operated devices will allow for on-site calibration, reducing the need for sending tools to distant calibration labs.

Embracing these advancements won’t only streamline your calibration processes but also improve the longevity and reliability of your tools.

Questions

Can I Calibrate My Tools Myself or Should I Hire a Professional?

You can calibrate your tools yourself if you have the right knowledge and equipment, but hiring a professional’s often more reliable. It guarantees accuracy and saves time, especially for specialized or complex instruments. Choose based on your confidence.

What Are the Most Common Mistakes During Tool Calibration?

Calibration’s like dancing—miss a step, and you’re offbeat. Common mistakes include ignoring manufacturer specifications, using incorrect reference standards, and skipping warm-up times. Keep your tools in tune, or you might hit a sour note.

How Do Environmental Factors Affect Calibration Accuracy?

Environmental factors like temperature, humidity, and electromagnetic interference can skew your tool’s calibration accuracy. If you’re not mindful of these conditions, you might end up with inconsistent readings that lead to errors in your measurements.

Are There Tools That Never Require Calibration?

While not all tools are created equal, some fixed tools like rulers or protractors often don’t need calibration. However, you’ll still want to check them occasionally, just to keep everything in line.

How Can I Track My Calibration Schedule Effectively?

You can track your calibration schedule effectively by using a calendar app or spreadsheet. Set reminders for due dates, maintain organized records, and regularly review completed calibrations to guarantee all tools stay accurate and compliant.

Conclusion

In the grand symphony of precision, calibration plays the key that keeps your electrical tools in tune. Ignoring it can lead to discord, where safety falters and efficiency wanes. By embracing regular calibration, you’re not just nurturing your tools; you’re ensuring that every spark of energy flows harmoniously. So, keep your instruments sharp, your measurements true, and dance with confidence in the rhythm of your work. Remember, a well-calibrated tool is music to your ears.