Importance of Insulation in Electrical Tools

Insulation in electrical tools is crucial for your safety and efficiency. It protects you from electric shocks and prevents short circuits that can damage your tools. Different insulation materials, like rubber and PVC, offer various advantages, ensuring durability and resistance to elements. Regular inspections help you catch issues like frays or heat buildup early. Taking care of your tools not only keeps them running longer, but also enhances your productivity. There’s more to explore about this essential topic.

Key Takeaways

- Insulation protects users from electric shocks, significantly enhancing safety while operating electrical tools.

- Proper insulation prevents short circuits, leading to more reliable tool performance and reduced downtime.

- It minimizes heat buildup during operation, helping to prevent overheating and potential tool failure.

- Insulated tools provide better grip and handling, contributing to increased comfort and productivity for users.

- Regular maintenance and inspection of insulation enhance tool longevity and overall efficiency in electrical tasks.

Understanding Electrical Insulation

When it comes to safety in electrical work, understanding electrical insulation is essential. Insulation acts as a barrier between conducting materials and you, preventing accidental shocks and ensuring safe operation.

It’s vital to know how different insulating materials work and where they’re used. Common types include rubber, plastic, and fiberglass, each with unique properties, such as resistance to heat and moisture.

You need to inspect insulation regularly for wear and damage. Damaged insulation can lead to electrical faults, increasing the risk of fire or electric shock.

Always choose tools with high-quality insulation tailored for your specific tasks. By prioritizing electrical insulation, you’ll not only protect yourself but also enhance the overall safety of your working environment. Moreover, understanding industry standards ensures that you select the most appropriate insulation for your tasks.

Benefits of Proper Insulation in Tools

Proper insulation in electrical tools not only enhances safety but also improves performance and longevity. When you use well-insulated tools, you’re protected against electric shocks, which can lead to serious injuries. This insulation also prevents short circuits, ensuring your tools run efficiently longer, saving you money on repairs and replacements.

Additionally, proper insulation minimizes heat buildup during operation, which can lead to overheating and potential damage. You’ll find that insulated tools offer better grip and handling, making your work more comfortable. Regular calibration of these tools is also essential, as it helps maintain tool reliability, ensuring accurate measurements and reducing the risk of errors.

With reliability as a priority, investing in tools with proper insulation means fewer interruptions and increased productivity. Overall, using well-insulated electrical tools keeps you safe while boosting your work efficiency and prolonging the life of your equipment.

Types of Insulation Materials

Choosing the right insulation material is key to maximizing the advantages of electrical tools. There are several types you might consider.

Rubber insulation is flexible and durable, perfect for tools that require constant maneuvering. PVC, or polyvinyl chloride, is another sturdy option, offering excellent resistance to abrasion and moisture, making it ideal for outdoor use.

Then there’s thermoplastic insulation, which provides great heat resistance and is widely used in many power tools. Finally, look into composite materials, which can combine various properties for enhanced performance.

Identifying Insulation Failures

Identifying insulation failures can pose serious risks to both safety and tool performance.

To identify these failures, start by visually inspecting your tools for signs of wear, such as cracks, frayed wires, or discoloration. If you notice any damage, it’s essential to address it immediately.

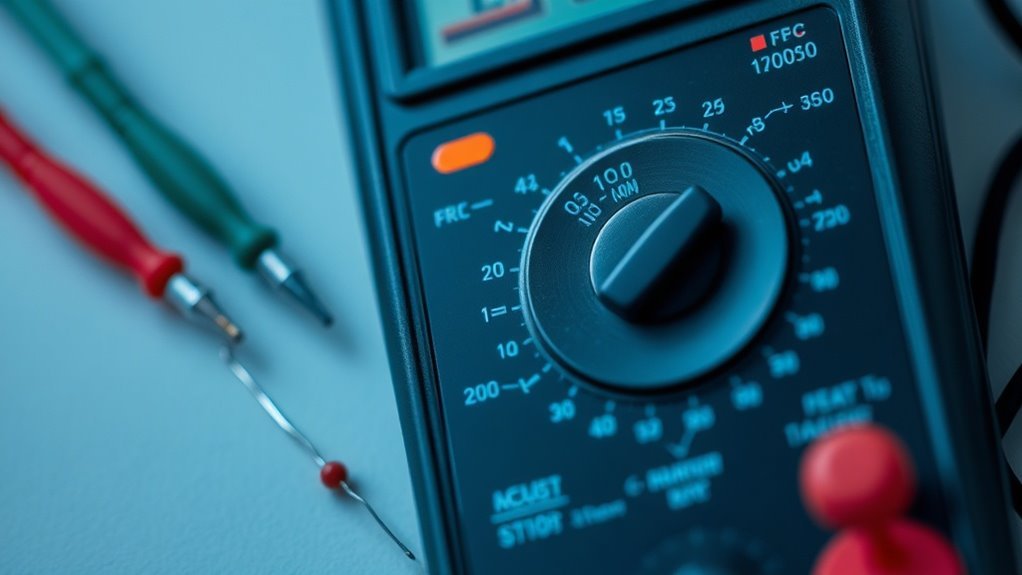

Another effective method is to perform a continuity test using a multimeter; if the reading shows a short circuit or unexpected connectivity, the insulation may be compromised.

Additionally, pay attention to any unusual heat or smell during operation, as these can indicate overheating or electrical leakage. Regularly checking your tools can help you catch insulation issues early, preventing costly repairs and keeping you safe while you work. Moreover, incorporating tools like fuse testers can enhance your overall electrical safety by ensuring that your electrical systems function correctly.

Always prioritize safety when handling electrical tools!

Best Practices for Tool Maintenance and Insulation

Neglecting routine maintenance can lead to insulation failures and compromise the safety of your electrical tools.

To prevent this, start with regular inspections. Check for cracks, frayed wires, or any signs of wear. If you spot any damage, replace or repair the insulation immediately.

Keep your tools clean and dry; moisture can deteriorate insulation over time. Store your tools in a climate-controlled environment, avoiding extreme temperatures or humidity.

Use tool covers or cases to protect them from dust and accidental damage.

Additionally, using essential tools like circuit testers can enhance your ability to safely assess the condition of your electrical systems.

Finally, make it a habit to read manufacturer guidelines for care and maintenance.

This proactive approach will help guarantee your tools remain safe and effective, ultimately prolonging their lifespan and performance.

Questions

How Does Temperature Affect Insulation Performance in Electrical Tools?

Temperature can considerably affect insulation performance in electrical tools. When it’s too hot, insulation materials can degrade, leading to increased resistance. In cold, insulation may become brittle, compromising its protective qualities and overall safety.

Can Insulation Wear Out Over Time?

Yes, insulation can wear out over time due to factors like heat, moisture, and mechanical stress. It’s vital to regularly inspect your tools to guarantee their insulation remains effective and safe for use.

What Certifications Should I Look for in Insulated Tools?

When choosing insulated tools, look for certifications such as IEC 60900 or ASTM F1505. These guarantee safety standards are met. Trust verified tools; safety’s not just an option, it’s essential for your work!

How Can I Tell if My Tools Are Properly Insulated?

You can tell if your tools are properly insulated by checking for visible damage, ensuring they’re rated for the voltage you’ll be using, and testing them with a multimeter for continuity and insulation resistance.

Are There Specific Brands Known for Superior Insulation in Tools?

Like a well-crafted shield, brands like Klein Tools, Milwaukee, and DeWalt are known for superior insulation in their electrical tools. It’s best to check for certifications to guarantee you’re getting the safest products.

Conclusion

In summary, understanding insulation in electrical tools isn’t just for engineers—it’s vital for anyone who uses these tools. Proper insulation keeps you safe and improves tool performance, making your work more efficient. While some might think that checking insulation is too time-consuming, remember that a little effort now can save you from serious accidents later. So, take a moment to inspect your tools; your safety and their longevity are worth it!