Role of Heat Shrink Tubing and Heat Guns

Heat shrink tubing and heat guns are essential tools for protecting and insulating electrical connections. When you heat the tubing, it shrinks to form a tight, durable barrier around wires, shielding them from moisture, dust, and abrasion. A heat gun offers a controlled way to apply the necessary heat, making the process more efficient and safe. With the right techniques, you can guarantee strong, reliable connections. Discover more about their types and techniques to enhance your projects.

Key Takeaways

- Heat shrink tubing insulates and protects wires from moisture, dust, and abrasion, ensuring reliable electrical connections.

- Various tubing types, like polyolefin and dual-wall, cater to different protection needs in electrical applications.

- Heat guns provide controlled heating to shrink tubing evenly, preventing damage to components.

- Proper technique ensures a snug fit and strong seals, enhancing the durability of electrical connections.

- Safety precautions, such as wearing goggles and gloves, are crucial when using heat shrink tubing and heat guns.

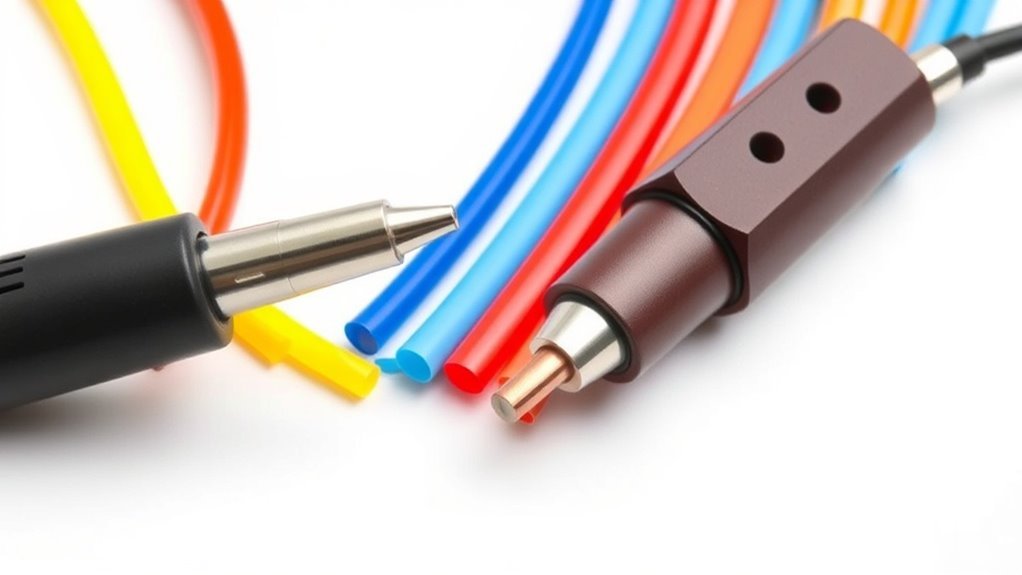

Understanding Heat Shrink Tubing

Heat shrink tubing is a versatile solution for protecting and insulating wires and cables. It’s made from a polymer that shrinks when exposed to heat, tightly conforming to the shape of the underlying surface.

This snug fit not only shields against environmental elements like moisture, dust, and chemicals, but also prevents abrasion and wear. When you apply heat, the tubing shrinks to half its original diameter and provides a durable barrier.

Plus, it comes in various sizes and colors, making it easy to select the right option for your specific project. Understanding how heat shrink tubing works is essential; it can enhance the longevity of your wiring and offer a clean, professional finish, ensuring your connections are secure and reliable.

Types of Heat Shrink Tubing

When choosing the right heat shrink tubing for your project, it’s important to understand the different types available. Each type serves specific applications and environments. Here’s a quick overview:

| Type | Material | Typical Uses |

|---|---|---|

| Polyolefin | Cross-linked | General electrical |

| PVC | Flexible plastic | Wire insulation, protection |

| Fluoropolymer | High-temperature | Chemical resistance |

| Neoprene | Rubber-like | Weatherproofing |

| Dual-wall | Adhesive-lined | Waterproof seals |

Selecting the appropriate type guarantees durability and effectiveness for your needs. Remember to ponder factors like shrink ratio and operating temperature to achieve the best results in your projects.

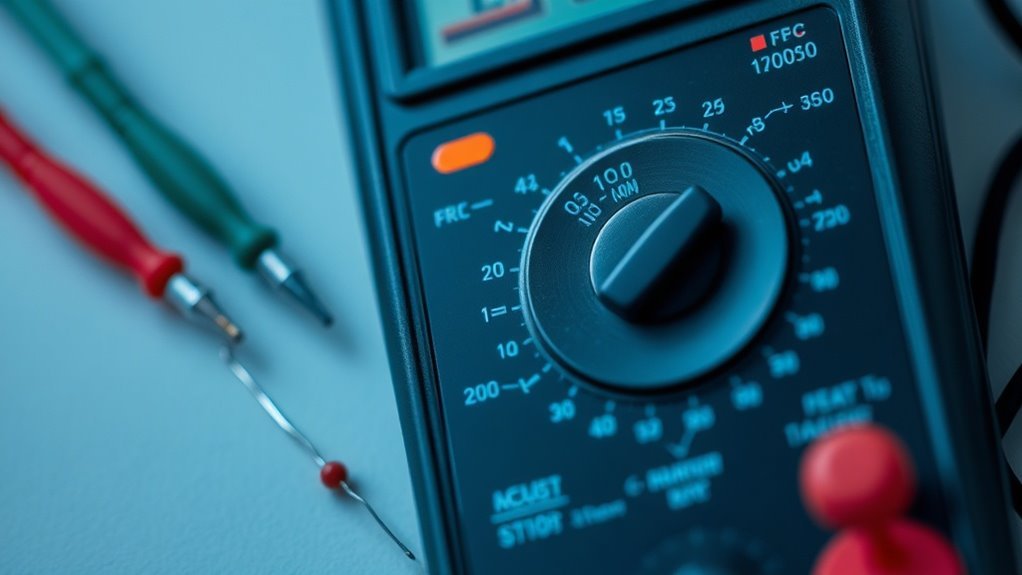

The Functionality of Heat Guns

While you might be familiar with the concept of heat guns, understanding their functionality can enhance your projects considerably.

Heat guns operate by blowing hot air, allowing you to apply controlled heat to various materials. This feature is particularly useful for shrinking heat shrink tubing, removing paint, or softening adhesives. They come with adjustable temperature settings, so you can tailor the heat according to your project needs.

Heat guns blow hot air for precise heating, perfect for tasks like shrinking tubing, paint removal, and adhesive softening.

With no need for open flames, heat guns offer safety and precision, making them ideal for DIY enthusiasts and professionals alike. Additionally, their ergonomic design allows for comfortable handling, ensuring you can work efficiently.

Knowing how to use a heat gun effectively can dramatically improve your results and elevate your projects.

Effective Application Techniques

To guarantee your heat shrink tubing is applied effectively, it’s important to understand the right techniques for using a heat gun. Start by selecting the correct size of tubing for your project; it should fit snugly over the wires or components.

Position the heat gun about 6 inches away from the tubing to avoid overheating and causing damage. Begin by applying heat evenly, moving the gun in a circular motion. This ensures that the tubing shrinks uniformly without hotspots.

Once it’s fully shrunk, let it cool undisturbed for a few minutes to set properly. Remember, practice makes perfect, so take your time and assess your results. Using these techniques will lead to a strong, insulated connection every time.

Safety Considerations and Best Practices

Although using a heat gun for heat shrink tubing can be straightforward, safety should always be a priority. When you’re handling high temperatures, it’s vital to take precautions to protect yourself and your workspace.

Here are some best practices to keep in mind:

- Use Personal Protective Equipment: Always wear safety goggles and heat-resistant gloves to prevent burns and eye injuries.

- Maintain a Safe Distance: Keep the heat gun at a safe distance from the tubing and surrounding materials to avoid overheating or igniting anything flammable.

- Keep Work Area Clean: Guarantee your workspace is free from clutter and flammable substances to minimize risks during your project.

- It’s also important to ensure that any electrical components, such as high-quality extension cords, are rated for the voltage you are using to avoid electrical hazards.

Questions

Can Heat Shrink Tubing Be Reused After Application?

No, you can’t really reuse heat shrink tubing after it’s been applied. Once it’s heated and shrunk, it forms a tight seal that doesn’t return to its original state, rendering it ineffective for further use.

What Is the Ideal Temperature for Using a Heat Gun?

The ideal temperature for using a heat gun generally ranges from 250 to 300 degrees Fahrenheit. You’ll achieve efficient shrinkage without damaging the tubing or surrounding components by staying within this range. Always monitor closely!

Are There Any Alternatives to Heat Shrink Tubing?

Yes, there are alternatives to heat shrink tubing, like electrical tape, liquid fish paper, silicone sealant, or epoxy. These options can provide insulation and protection, though they might not match heat shrink’s effectiveness in every scenario.

How Long Does Heat Shrink Tubing Last Once Applied?

Once you’ve applied heat shrink tubing, it can last several years—sometimes a decade or more—if properly maintained. Just think of it like a trusty smartphone; with care, it’ll keep doing its job efficiently.

Can I Use a Hair Dryer Instead of a Heat Gun?

You can use a hair dryer, but it’s less effective than a heat gun. The temperature may not reach high enough, and it might take longer, so results could vary. A heat gun’s better overall.

Conclusion

To sum up, you’ve seen how heat shrink tubing and heat guns work together seamlessly to provide effective insulation and protection. By choosing the right type and applying it correctly, you can guarantee reliable results. Safety’s key, so don’t forget to follow best practices while you heat and shrink. Coincidentally, mastering these techniques not only simplifies your projects but also enhances your confidence. So, grab those tools and get started—your next successful application awaits!