The Science Behind Brushless Motors in Power Tools

Brushless motors in power tools work by using permanent magnets and electronic control for efficient performance. Without brushes, they reduce friction and heat, leading to longer lifespan and enhanced torque. This means you get more power with less energy, extending battery life considerably. Plus, they’re easier to maintain thanks to fewer moving parts. If you’re curious about how these innovations impact your projects, you’ll want to explore further into their components and applications.

Key Takeaways

- Brushless motors utilize permanent magnets in the rotor and electronic commutation, enhancing efficiency by eliminating friction from brushes.

- Control electronics and sensors manage the operation of brushless motors, allowing for precise speed regulation and torque adjustments.

- The absence of brushes reduces wear and maintenance, resulting in longer lifespans and improved durability in power tools.

- Brushless motors deliver higher torque and quieter operation, making them effective for demanding tasks and increasing user comfort and project efficiency.

- Electronic Speed Controllers (ESCs) ensure safe, efficient power output, adapting to varying loads and preventing overheating in brushless motors.

Understanding the Basics of Brushless Motors

While many power tool users mightn’t know the difference, understanding brushless motors can greatly enhance your experience and efficiency.

Brushless motors are designed without brushes, which means fewer moving parts and less friction. This leads to increased longevity and durability in your power tools.

Brushless motors minimize moving parts and friction, resulting in enhanced durability and longevity for your power tools.

You’ll also notice improved performance and efficiency, as these motors provide more torque and run cooler than traditional brushed motors. Plus, they consume less battery power, meaning you can work longer before needing a recharge.

The advanced technology allows for precise control and reduced maintenance, making your tasks smoother and more enjoyable. By opting for brushless motors, you’re investing in tools that help you get the job done faster and with greater reliability.

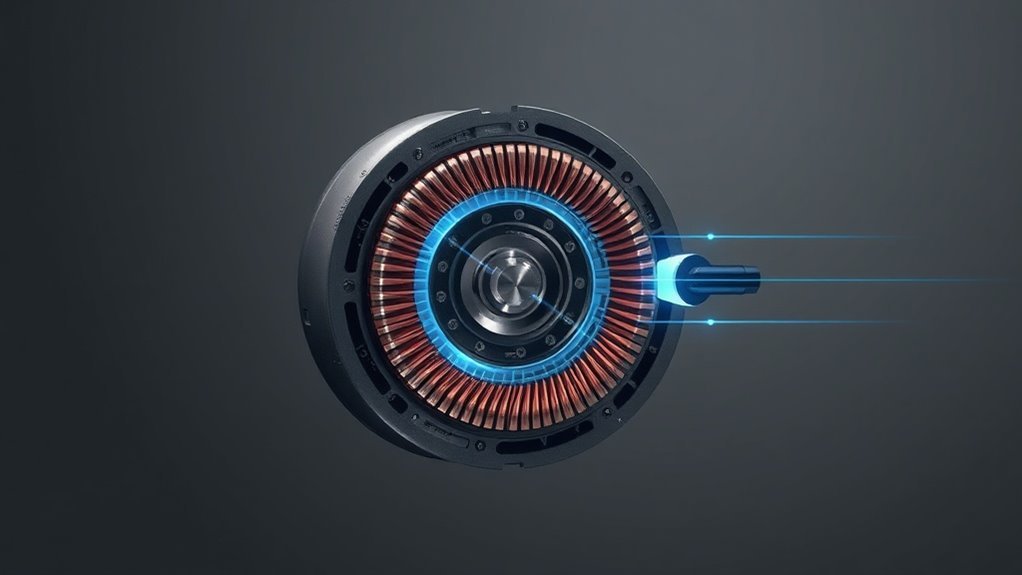

Components of a Brushless Motor

When you look at brushless motors, understanding their components is key to grasping how they work effectively.

You’ll want to pay attention to rotor design dynamics, stator configuration insights, and the role of control electronics.

Each element plays an essential part in optimizing performance and efficiency in power tools.

Rotor Design Dynamics

Understanding rotor design dynamics is vital for optimizing the performance of brushless motors in power tools. The rotor is a significant component that directly influences efficiency and torque output.

You’ll find the rotor comprises permanent magnets, usually arranged to create a strong magnetic field. The shape and size of the rotor equally matter; they affect how smoothly the motor operates and how much power it can deliver.

Precision in manufacturing guarantees minimal air gap between the rotor and stator, enhancing performance. Additionally, balancing the rotor is important to reduce vibration, increasing tool lifespan and user comfort.

Stator Configuration Insights

The stator configuration plays an essential role in the operation of brushless motors, as it directly impacts the efficiency and overall performance of your power tools.

The stator, which houses the winding coils, generates a rotating magnetic field that interacts with the rotor. You’ll find that the number of poles and the winding arrangement influence torque production and power delivery.

A well-designed stator optimizes the magnetic interaction, considerably improving your tool’s efficiency. Furthermore, configurations like concentrated or distributed windings can also affect the motor’s thermal performance and noise levels.

Control Electronics Functionality

Control electronics bring brushless motors to life by managing their operation and ensuring peak performance. These components include a microcontroller, gate drivers, and sensors like Hall effect sensors.

The microcontroller interprets feedback from the sensors to determine the motor’s position and speed, allowing it to adjust power delivery efficiently. Gate drivers then convert low-voltage control signals into high-voltage pulses, which energize the motor’s phases in the correct sequence.

This precise control enhances torque and efficiency, reducing energy waste. Plus, the ability to vary speed and power makes your power tools adaptable to various tasks.

In short, control electronics are the unsung heroes that optimize your brushless motor’s performance, making your tools more functional and reliable.

How Brushless Motors Operate

Brushless motors operate on electromagnetic principles that set them apart from traditional motors.

You’ll see how the commutation process works to enhance efficiency and performance in your power tools.

Understanding these concepts will help you appreciate the advantages of choosing brushless technology.

Electromagnetic Principles Explained

Many people mightn’t realize that brushless motors operate on a unique set of electromagnetic principles that enhance their efficiency and durability.

At the core of these motors are the electromagnetic fields generated by coils of wire and permanent magnets. When electricity flows through these coils, it creates a magnetic field that interacts with the magnets, causing motion.

Since there are no brushes, there’s less friction and heat, resulting in higher efficiency and longer life. This design allows you to harness much more power without a significant increase in size or weight.

Commutation Process Defined

While the internal workings of brushless motors can seem complex, the commutation process is actually quite straightforward. This process involves the electronic switching that directs the flow of current through the motor’s windings. Unlike traditional motors, brushless designs eliminate the need for mechanical brushes, enhancing reliability.

Here’s a quick look at how commutation works:

| Step | Action | Result |

|---|---|---|

| 1 | Sensor detects position | Activates the appropriate coil |

| 2 | Current flows | Generates magnetic field |

| 3 | Rotor aligns | Creates rotation |

| 4 | Sensor updates | Switches to next coil |

| 5 | Repeat process | Sustains motor operation |

This continuous cycle guarantees smooth and efficient power delivery, essential for peak performance.

Efficiency and Performance Benefits

As you explore the world of power tools, you’ll quickly discover that brushless motors deliver exceptional efficiency and performance advantages.

These motors eliminate friction and energy loss, making them a game-changer for serious DIYers and professionals alike. You’ll notice how they provide more power while using less energy, translating to longer run times and faster task completion.

With fewer maintenance needs, you can focus more on your projects and less on upkeep.

- Experience longer battery life

- Enjoy quieter operation

- Feel the power in your hands

- Complete tasks faster than ever

- Benefit from a lightweight design

Choosing brushless motors means you’re investing in tools that truly enhance your skill, efficiency, and enjoyment in every project you tackle.

Comparing Brushless and Brushed Motors

When choosing between brushless and brushed motors for power tools, it’s crucial to understand their fundamental differences.

Brushed motors use carbon brushes to transfer electrical energy, which can lead to increased wear and maintenance needs over time. They’re often cheaper and simpler, making them a go-to for casual users.

Brushed motors, relying on carbon brushes, are economical but may require more maintenance due to wear over time.

However, brushless motors eliminate these brushes, relying instead on electronic controls. This results in less friction and heat, providing longer lifespans and improved performance.

Brushless motors can handle more demanding tasks but come at a higher initial cost.

Basically, if you prioritize durability and efficiency, brushless is the way to go, while brushed motors might suit lighter tasks and budgets better.

Benefits of Brushless Motors in Power Tools

When you choose brushless motors for your power tools, you’ll notice a significant boost in energy efficiency, which means less power wasted during use.

Plus, these motors have a longer lifespan compared to brushed counterparts, saving you money in the long run.

Understanding these benefits can help you make better choices for your projects.

Increased Energy Efficiency

Brushless motors are revolutionizing power tools by greatly boosting energy efficiency. With these motors, you’re not only getting more power but also maximizing battery life, making your job easier and saving you money in the long run.

You’ll experience improved torque and speed, enabling you to tackle tougher tasks with less energy. Plus, less wasted energy means you’re reducing your carbon footprint, contributing to a greener planet!

- Feel the thrill of longer battery runs

- Enjoy consistent performance without overheating

- Experience lighter tools that don’t fatigue your hands

- Save money on electricity and replacements

- Savor the satisfaction of choosing eco-friendly technology

Extended Tool Lifespan

The advantages of brushless motors don’t stop at energy efficiency; they also greatly extend the lifespan of power tools. Unlike traditional brushed motors, brushless motors have fewer moving parts, which means less wear and tear over time. This reduction in friction leads to less heat generation, ultimately preserving the components of your tools.

Additionally, brushless motors operate more efficiently, reducing energy waste and the strain on the motor. When you use a brushless power tool, it can handle more demanding tasks without overheating or breaking down.

This durability not only saves you money on replacements but also allows you to tackle more projects without constantly worrying about your tool’s condition.

Enhancing Efficiency and Performance

As power tools evolve, enhancing efficiency and performance becomes essential for users seeking the best results.

Brushless motors play an important role in this transformation, offering a level of power and precision that’s often unmatched. You’ll notice the difference in your projects, experiencing smoother operation and increased runtime.

Consider these advantages:

- Higher torque for tackling tough materials effortlessly.

- Reduced noise levels that create a more pleasant working environment.

- Longer battery life so you can work longer without interruption.

- Less vibration that leads to comfortable handling.

- Faster task completion, giving you more time for other pursuits.

With brushless motors, you’re not just getting a tool; you’re investing in enhanced performance that empowers your work.

The Role of Electronic Speed Controllers

Electronic speed controllers (ESCs) are essential for managing the power output in brushless motors, enabling precise speed regulation and enhancing overall tool performance.

They effectively modulate the flow of electrical energy to the motor, allowing you to adjust speed and torque according to your specific needs. By integrating smart feedback systems, ESCs can respond to changing loads, ensuring the motor operates efficiently under varying conditions.

ESCs optimize electrical energy flow, enabling precise speed and torque adjustments while adapting to varying loads for efficient motor performance.

This responsiveness not only maximizes battery life but also improves runtime, which is vital for both casual users and professionals. Additionally, modern ESCs feature safety mechanisms that protect against overheating and overcurrent, providing you peace of mind while you work on demanding tasks. Moreover, advancements in rechargeable battery technology complement the efficiency of brushless motors, further extending their performance and usage time.

In short, ESCs are key to revealing the full potential of your brushless tools.

Applications in DIY and Professional Settings

Whether you’re a weekend warrior tackling home improvement projects or a professional tradesperson looking for reliable performance on the job, brushless motors in power tools offer significant advantages.

These motors provide enhanced efficiency, longer run times, and less maintenance, ensuring you get the most out of your tools. In both DIY and professional settings, brushless motors deliver precision and power that can make all the difference. Additionally, understanding the differences in energy consumption between corded and cordless options can help you maximize your efficiency.

- You’ll finish projects faster, leaving more time for what matters.

- Enjoy the thrill of bringing your vision to life.

- Experience the satisfaction of flawless results.

- Feel the reliability in every cut, drill, or drive.

- Trust that your tools won’t let you down, project after project.

Maintenance and Longevity of Brushless Motors

Brushless motors aren’t just about enhanced performance; they also offer advantages when it comes to maintenance and longevity. Since they lack brushes, you won’t need to worry about brush replacement or the wear that comes with them. This means less downtime for you and more efficient operation over time.

The sealed design also helps keep dust and debris out, reducing the frequency of cleaning required. As a result, your power tools can last considerably longer, saving you money in the long run.

Regularly check the bearings and cooling vents to verify everything runs smoothly, but overall, brushless motors provide a reliable and low-maintenance option that keeps your tools performing at their best for years.

The Future of Brushless Technology in Power Tools

As the demand for more efficient and powerful tools grows, advancements in brushless technology are set to shape the future of power tools.

You can expect innovations that not only enhance performance but also bring a new level of convenience and safety to your projects. Imagine tools that last longer, charge faster, and function more quietly, allowing you to focus on your craft without interruption.

- Increased battery life means you can work longer without breaks.

- Compact designs allow for better maneuverability in tight spaces.

- Advanced features increase precision and control, leading to better results.

- Eco-friendly options reduce your carbon footprint.

- Intuitive controls simplify operation, making tools accessible to everyone.

Additionally, the integration of Bluetooth and app functionalities is set to revolutionize how you interact with your tools.

The future looks bright for power tool enthusiasts like you!

Questions

Can Brushless Motors Run on Standard Batteries?

Yes, brushless motors can run on standard batteries, but it depends on the voltage and capacity requirements of the specific motor. Be sure to match the battery specifications to guarantee peak performance and longevity.

How Do I Know if My Tool Has a Brushless Motor?

About 70% of high-end power tools now feature brushless motors. Check your tool’s specifications or look for labels stating “brushless.” You might also notice longer run times and less noise while using it.

Are Brushless Motors Quieter Than Brushed Motors?

Yes, brushless motors tend to be quieter than brushed motors. They generate less noise due to their design, which reduces friction. So, if noise is a concern for you, brushless tools are a great choice.

Do Brushless Motors Require Special Maintenance?

Brushless motors are like superheroes in the world of maintenance! You don’t have to worry much about them; they require minimal upkeep, just some occasional cleaning and proper storage to keep them running smoothly.

What Features Enhance Brushless Motor Performance?

Optimized electronic control, higher efficiency, and improved thermal management enhance brushless motor performance. They also benefit from minimal friction, resulting in longer operational life and lower energy consumption, making them ideal for demanding applications.

Conclusion

In a world where power tools reign supreme, brushless motors are the superheroes you’ve been waiting for! They’re not just a trend; they’re the high-tech marvel making your DIY dreams soar! With less maintenance and unmatched efficiency, these motors are practically the Swiss Army knife of power tools. Imagine cutting through materials with the ease of slicing butter! So, ditch those outdated brushed motors and embrace the unstoppable force of brushless technology—your projects will never be the same!