The Science of Soldering and How It Bonds Metals

Soldering’s science lies in its ability to bond metals through a carefully crafted alloy of tin, lead, and sometimes silver or copper. Proper heat management is key; the right temperature guarantees effective bonding without damaging components. Flux plays a crucial role, removing oxidation and promoting adhesion. By preparing surfaces well and using the right techniques, you can create strong joints. There’s a lot more to learn about mastering these skills and the latest advancements in soldering technology.

Key Takeaways

- Soldering involves melting an alloy, usually tin and lead, to create a strong electrical and mechanical bond between metal components.

- The flux in soldering improves adhesion by removing oxidation and preventing future oxidation on metal surfaces.

- Proper heat management is critical; maintaining ideal temperatures ensures effective metal bonding without damaging components.

- Surface preparation enhances solder flow and joint strength through clean, smooth surfaces free of contaminants.

- Advancements in soldering techniques, such as lead-free alloys and robotic systems, improve bond quality and device reliability.

Understanding Solder and Its Composition

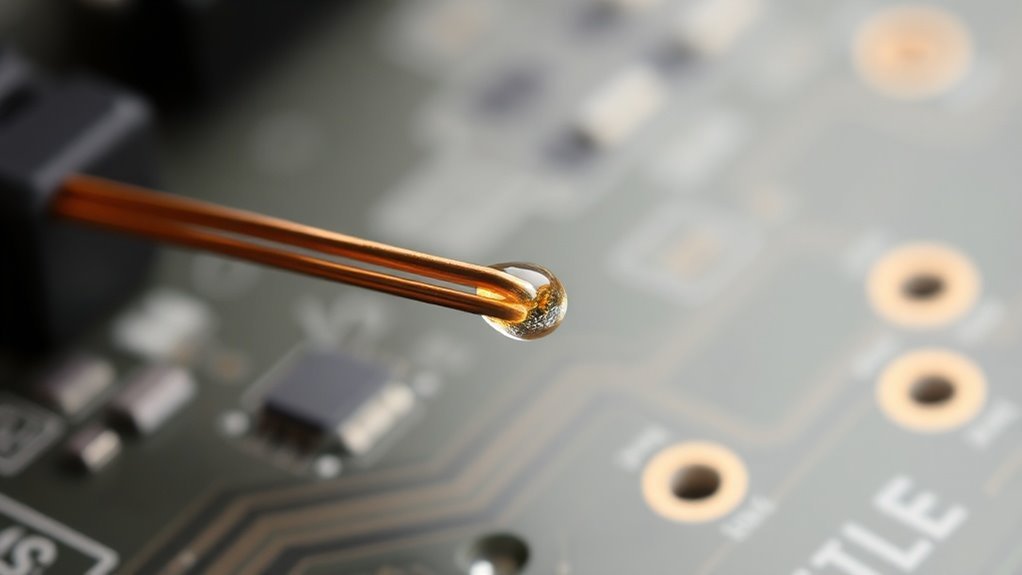

Solder, an essential material in metalworking, is primarily used for joining metal components. It’s a fusible alloy, meaning it melts at relatively low temperatures, which makes it perfect for electronics and plumbing applications.

Typically composed of tin and lead, you’ll also find variations that use silver, copper, or other metals to enhance properties like strength and conductivity. Understanding solder‘s composition is fundamental because it influences its melting point, flow characteristics, and overall bonding reliability.

You’ll often encounter different solder types suited for specific tasks, like rosin-core solder for electronics. By grasping these differences, you can select the right solder for your project, ensuring strong joints and preventing potential failures down the line.

The Role of Heat in the Soldering Process

When soldering, controlling the temperature is essential to guarantee that both solder and base metals reach their appropriate melting points without causing damage.

You’ll need to understand how heat transfers through the materials, as this can greatly affect the bond quality.

Keeping these factors in mind will help you achieve a strong and reliable connection.

Temperature Control Importance

Effective temperature control is essential for successful soldering, as even slight variations can greatly impact the quality of the bond. If the temperature’s too low, the solder won’t melt properly, leading to weak joints. Conversely, overheating can damage sensitive components or create excessive oxidation.

The following table highlights the importance of temperature control:

| Temperature Range | Effect on Soldering |

|---|---|

| 180-210°C | Ideal for most electronic solder |

| Below 180°C | Incomplete melting of solder |

| Above 210°C | Risk of component damage |

| 220-245°C | Suitable for heavy-duty joints |

| Over 250°C | Severe oxidation and failure |

Maintaining the right temperature guarantees strong, reliable connections in your projects. Always monitor your heat source during the process!

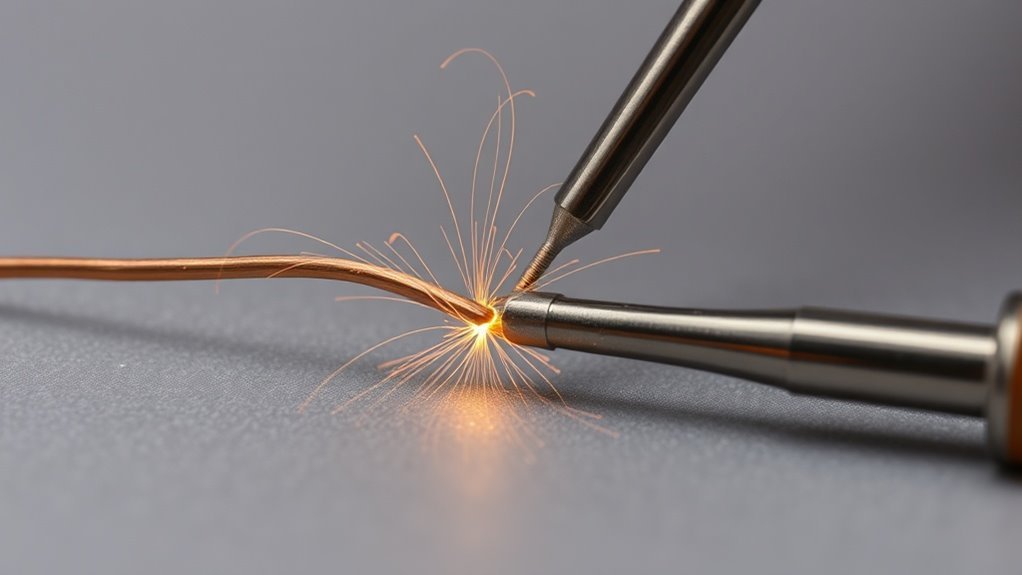

Heat Transfer Mechanism

Keeping the right temperature in mind, understanding heat transfer mechanisms is key to the soldering process. When you apply heat, it travels from the soldering iron through the solder and into the metal surfaces. This conduction is essential, as it helps thin layers of solder melt and flow.

You’ll notice that the solder needs to reach a certain temperature to properly adhere to the metals you’re joining.

Moreover, ambient temperature and airflow can affect how quickly heat transfers. By controlling your heat source and being mindful of your surroundings, you can achieve ideal results.

Melting Point Considerations

In soldering, understanding melting point considerations is essential for a successful bond. You’ll need to guarantee the solder’s melting point is lower than that of the metals being joined. If you apply too much heat, you risk damaging the components.

Typically, soldering alloys melt at around 180-230°C, while the base metals might require considerably higher temperatures to melt.

Using a solder with a suitable melting point not only facilitates bonding but also secures that your workpiece remains intact. When you heat the metal, it should reach a temperature that allows the solder to flow but not so high that it compromises the integrity of the components.

Balancing these temperatures is key to achieving a reliable joint.

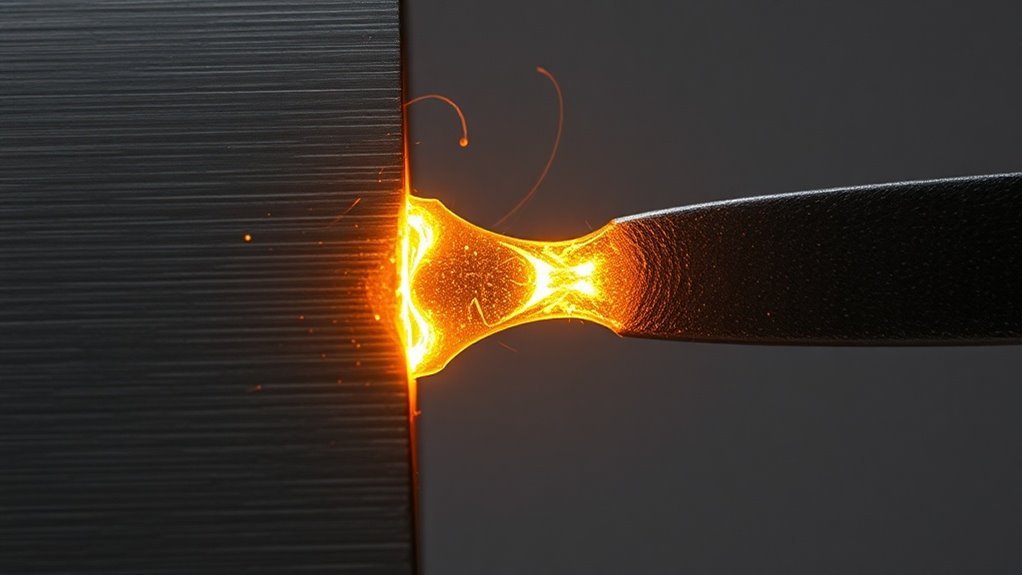

The Importance of Flux in Achieving Strong Joints

Although many factors contribute to the quality of solder joints, flux plays a crucial role in ensuring strong and reliable connections.

It helps remove oxidation from the metal surfaces, allowing the solder to flow smoothly and bond effectively. Without flux, you’re likely to encounter weak joints or, worse, complete failure due to poor adhesion.

Additionally, flux acts as a protective barrier against future oxidation during the soldering process, enhancing the durability of your joints.

When you choose the right type of flux for your project, you’re fundamentally setting the stage for a successful outcome.

Metals and Their Compatibility With Solder

Understanding the compatibility of different metals with solder is essential for ensuring successful joints. Not all metals bond well with solder, which can lead to weak connections.

For instance, copper and brass are excellent candidates, as they readily accept solder, creating reliable joints. On the other hand, metals like aluminum can pose challenges because of their oxide layer, which prevents proper adhesion.

Stainless steel often requires a specific type of solder to achieve a solid bond. When working with any metal, it’s crucial to know its properties and how they interact with solder.

Doing this minimizes the risk of failure in your projects, ultimately leading to better results and durability in your applications. Choose wisely for effective soldering.

Techniques for Effective Soldering

When you’re soldering, effective techniques can make all the difference.

Start by preparing your surfaces properly, choosing the right type of solder, and mastering temperature control. These steps will help guarantee strong and reliable bonds.

Preparation of Surfaces

Preparing surfaces properly is essential for effective soldering. Start by cleaning the metal parts you plan to join. Use a wire brush or sandpaper to remove dirt, oxidation, and old solder. You want a smooth, shiny surface to promote a strong bond.

After cleaning, use a suitable solvent, like isopropyl alcohol, to eliminate any grease or residue that could interfere with adhesion. Once the surfaces are clean, it’s often helpful to apply a thin coating of flux, which helps prevent oxidation and enhances solder flow.

If you’re soldering dissimilar metals, verify both surfaces are adequately prepared for best results. Remember, the time invested in preparation pays off with a stronger, more reliable joint.

Choosing the Right Solder

After guaranteeing surfaces are clean and ready, the next step involves selecting the right solder for your project. Different solder types cater to various applications, so it’s essential to choose wisely. You’ll find solders come in different alloys, with lead and lead-free options being the most common. Consider factors like conductivity, melting point, and compatibility with your materials. Below is a helpful table to guide your decision:

| Solder Type | Melting Point (°C) | Use Case |

|---|---|---|

| Leaded | 183-190 | Electronics |

| Lead-Free | 217-227 | Environmental safety |

| Silver | 217-240 | Jewelry |

| Tin/Antimony | 232-260 | Plumbing |

Using the right solder guarantees a strong and lasting bond.

Temperature Control Techniques

Proper temperature control is essential for effective soldering, as it guarantees a solid connection without damaging your components.

To maintain the right temperature, always use a reliable soldering iron with adjustable heat settings. Start by preheating your iron to the recommended temperature for the solder you’re using, typically between 350°F to 450°F (175°C to 230°C).

When soldering, apply heat to the joint rather than the solder directly—this helps the solder flow and bond evenly. Keep your tip clean and tinned for better heat transfer.

If you’re working with sensitive components, consider using a heat sink to prevent overheating.

Finally, monitor your working environment, as drafts or cold surfaces can affect temperature stability, risking poor solder connections.

Common Soldering Mistakes and How to Avoid Them

Soldering is a skill that can be tricky, and even experienced hobbyists often make common mistakes that lead to frustrating results. One frequent error is using too much solder; just enough should flow into the joint without excess pooling.

Additionally, failing to properly clean the surfaces can prevent solder from bonding effectively, so always prep your metals. Overheating components can damage sensitive parts, so remember to control your temperature carefully. Using a solder that’s inappropriate for the application can also produce weak joints, so choose wisely.

Finally, neglecting to support your workpieces can lead to movement and poor connections. By avoiding these pitfalls, you’ll improve your soldering results and gain greater confidence in your skills.

Testing and Evaluating Solder Joints

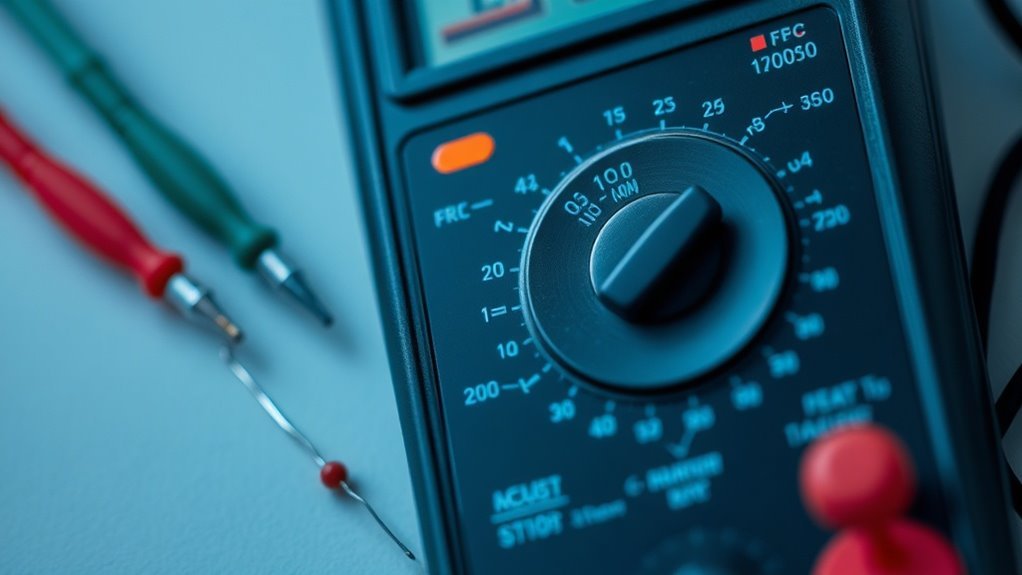

While you may feel confident in your soldering skills, effectively testing and evaluating your solder joints is essential to confirm their reliability and strength.

Here are some methods to verify your joints are up to par:

- Visual Inspection: Look for any irregularities, such as cracks, dull surfaces, or excess solder that may indicate poor bonding.

- Electrical Continuity Testing: Use a multimeter to check for continuity, verifying the joint conducts electricity properly and confirming there’s no break in the circuit.

- Mechanical Stress Testing: Gently apply force to the joint to assess its strength. A strong joint shouldn’t break or come apart easily.

Advancements in Soldering Technology and Materials

Recent innovations in soldering technology and materials have greatly enhanced the efficiency and effectiveness of electronic assembly.

One significant advancement is the development of lead-free solders, which not only comply with environmental regulations but also offer improved thermal and mechanical properties.

Additionally, the introduction of advanced soldering techniques, such as selective soldering and reflow processes, has simplified complex assembly tasks and reduced defects.

New materials like solder paste with enhanced flux formulations are also more forgiving, allowing for better wetting and adhesion.

You’ll find that automation, including robotic soldering systems, further streamlines production and boosts precision.

These advancements make soldering more reliable and consistent, ensuring that electronic devices meet increasingly demanding performance standards.

Questions

Can Soldering Be Done Without Specialized Equipment?

Yes, you can solder without specialized equipment. A simple soldering iron, solder wire, and a steady hand are enough for basic projects. Just guarantee you’re working safely and in a well-ventilated area.

What Are the Health Risks Associated With Soldering?

Soldering can expose you to harmful fumes and heavy metals, leading to respiratory issues, skin irritation, or long-term health problems. It’s essential to use proper ventilation and protective equipment to minimize these risks.

How Long Does a Solder Joint Typically Last?

A stitch in time saves nine, and typically, a solder joint can last several years if done correctly. However, it’s essential to evaluate factors like stress, environmental conditions, and quality of materials used.

Do Different Solder Types Affect Environmental Sustainability?

Yes, different solder types can impact environmental sustainability. Some contain harmful metals, while others are more eco-friendly. Choosing a sustainable solder can minimize environmental damage and promote healthier practices in electronics manufacturing.

Can I Solder Different Metals Together Successfully?

Soldering different metals together is like fitting puzzle pieces—sometimes they mesh, sometimes they don’t. You can succeed, but it often depends on the solder type and proper techniques to guarantee a reliable bond.

Conclusion

So, now that you’re a soldering expert, you might just think you can fuse metals like a pro! But remember, it’s not just about melting some fancy metal goo; it’s a delicate dance of heat, flux, and compatibility. Think you can skip the flux? Good luck with that! Just imagine your joints falling apart—voilà! You’ve created modern art instead of a solid connection. So, grab your soldering iron and show those metals who’s boss (after all, it’s not rocket science… oh, wait)!