Principles of Safe Wire Stripping and Cutting

When safely stripping and cutting wire, you need the right tools like adjustable wire strippers and sturdy cutters. Always wear safety goggles and insulated gloves to protect against injuries. Use proper techniques, such as not cutting too close to the wire’s base and disconnecting power before you start. Regularly maintain your tools to avoid accidents. By following best practices, you can guarantee reliable electrical connections. There are more important tips to keep in mind as you work.

Key Takeaways

- Always wear safety goggles and insulated gloves to protect against cuts, electric shocks, and flying debris while handling wires.

- Disconnect power before starting any wire stripping or cutting to prevent electrical hazards.

- Use high-quality, adjustable wire strippers and sturdy cutters to ensure clean cuts without damaging the wire.

- Regularly maintain and inspect tools for sharpness and signs of wear to minimize accidents during use.

- Follow best practices for electrical connections, including using proper insulation and connectors, to ensure safety and reliability.

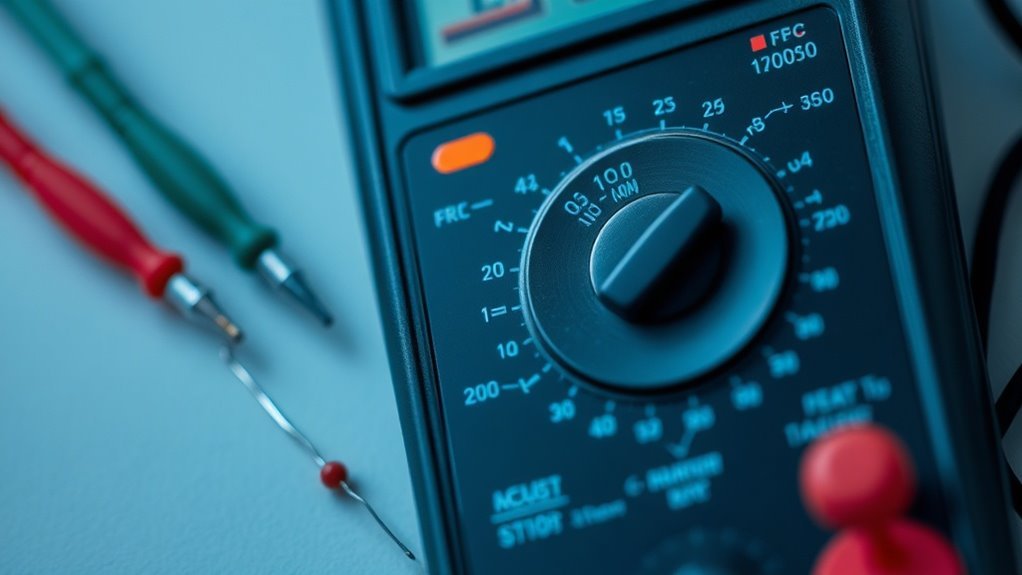

Essential Tools for Wire Stripping and Cutting

When it comes to wire stripping and cutting, having the right tools is crucial for a safe and efficient job. You’ll want to invest in high-quality wire strippers, which allow you to remove insulation without damaging the wire itself.

Look for adjustable options to accommodate different wire sizes. A sturdy pair of wire cutters is equally important—they should provide clean cuts without fraying the wire. A utility knife can be handy for tougher insulation as well.

Additionally, having safety glasses will protect your eyes from any debris. Don’t forget a reliable work surface and a voltage tester to guarantee safety before you start. Using tools like a circuit tester can greatly enhance your understanding of electrical systems and ensure that you’re working safely with electrical wires.

With the right tools, you’ll find your tasks are quicker and easier.

Understanding Wire Types and Gauges

Understanding the various wire types and gauges is vital for any wiring project. Wires come in different materials, like copper and aluminum, each offering unique properties.

Copper is a popular choice due to its excellent conductivity, while aluminum is lighter and often used in overhead power lines.

Gauge refers to the wire’s thickness, impacting its current-carrying capacity. Lower gauge numbers signify thicker wires, which can handle higher currents, while higher gauges indicate thinner wires, suitable for lower power applications.

Familiarize yourself with common gauges, such as 14 AWG for household wiring or 24 AWG for low-voltage projects. Knowing the right type and gauge guarantees your project’s efficiency and safety, helping you avoid potential hazards.

Safety Gear and Precautions

Before you begin any wiring project, it’s crucial to equip yourself with the right safety gear and precautions to minimize risks. Make sure you’re wearing safety goggles to protect your eyes from flying debris. Gloves are essential to prevent cuts and electrical shocks. Ear protection can also be important, especially when using power tools. It’s vital to ensure your safety gear meets safety standards to guarantee its effectiveness in protecting you.

Here’s a quick reference table to help you remember:

| Safety Gear | Purpose |

|---|---|

| Safety Goggles | Protects eyes from debris |

| Insulated Gloves | Prevents cuts and electric shock |

| Ear Protection | Reduces noise impact |

| Sturdy Footwear | Safeguards feet from heavy objects |

Proper Techniques for Wire Stripping

When it comes to wire stripping, using the right tools is vital for safety and efficiency.

You’ll also want to follow some essential safety precautions to guarantee you’re working securely.

Let’s explore the techniques that will help you strip wires like a pro while staying safe.

Tools for Wire Stripping

Choosing the right tools for wire stripping can make a significant difference in both safety and efficiency.

First, invest in a quality pair of wire strippers with adjustable gauge settings for various wire sizes. This’ll help you strip the insulation without damaging the wire itself.

A pair of diagonal cutters is essential for trimming wire ends cleanly. Additionally, consider using a wire cutting knife for precision jobs and tougher insulation.

Don’t forget a heat gun if you’re working with heat-shrink tubing. Finally, always keep your tools well-maintained; dull blades can cause accidents.

Familiarize yourself with each tool’s operation, so you can work confidently and effectively. With the right equipment, you’ll find wire stripping becomes a much simpler task.

Safety Precautions to Follow

While you may be enthusiastic to get started with wire stripping, prioritizing safety is essential to prevent accidents and injuries.

Always wear protective gear like safety goggles and gloves to shield yourself from flying debris and sharp wire ends. Verify your workspace is well-lit and free from clutter.

Check your tools for any damage before use; a faulty tool can lead to mishaps. When stripping wires, use the correct technique by placing the wire in the proper gauge slot of your stripper and applying even pressure.

Avoid using excessive force, as this can damage the wire or cause it to slip.

Finally, never work on live wires; always disconnect power to verify a safe environment.

Effective Methods for Wire Cutting

Although cutting wire might seem straightforward, using the right methods can make a significant difference in achieving clean, precise cuts. Here are some effective techniques to take into account:

- Use the Right Tool: Always opt for wire cutters or specialized tools suited for the wire gauge you’re working with.

- Angle Your Cut: Position your cutters at a slight angle to guarantee a smoother edge and minimize fraying.

- Support the Wire: Hold the wire tightly with one hand while cutting to keep it steady, which aids in making cleaner cuts.

Additionally, using well-insulated tools can enhance user safety and protect against potential electrical hazards while performing cutting tasks.

Identifying and Avoiding Common Mistakes

When you’re stripping and cutting wire, choosing the right tools is essential. Many people overlook the importance of proper safety gear and techniques, which can lead to accidents or damage. Additionally, implementing safety features like strain relief can help prevent electrical faults during the wire-stripping process.

Incorrect Tool Selection

Selecting the wrong tool for wire stripping and cutting can lead to accidents and damaged materials, so it’s crucial to choose the right equipment for the job.

Using improper tools not only increases the risk of injury but can also result in poor-quality work that’s costly to fix.

To avoid this, keep these points in mind:

- Use dedicated wire strippers instead of regular cutters to guarantee precise stripping and minimize wire damage.

- Choose the right size tool for the wire gauge; using mismatched tools can cause slips or cuts.

- Inspect your tools regularly to ascertain they’re in good condition; worn tools can make tasks more difficult and dangerous.

Being mindful of your tool selection sets the stage for safe and effective wire work.

Inadequate Safety Gear

Safety gear plays an essential role in preventing accidents during wire stripping and cutting. If you’re not wearing the proper protective equipment, you’re putting yourself at serious risk.

Always wear safety goggles to shield your eyes from flying debris and gloves to protect your hands from cuts and abrasions. Steel-toed boots can safeguard your feet from heavy tools or unexpected drops. A dust mask can also be beneficial if you’re working with insulation materials that might release harmful particles.

Don’t underestimate the importance of gear that fits properly; ill-fitting items can limit your movement or even become a hazard. Make sure you check your equipment regularly to avoid using worn-out safety gear. It’s a simple step that can save you from significant injuries.

Improper Cutting Techniques

A sharp wire cutter can make your tasks easier, but using improper cutting techniques can lead to accidents and damaged materials.

It’s vital to recognize common mistakes that can compromise your safety and the quality of your work. Here are some techniques to avoid:

- Cutting too close to the wire’s base: This can cause frayed ends and electrical shorts.

- Using excessive force: Applying too much pressure can break the cutter and lead to injuries.

- Cutting unsupported wire: Always guarantee that the wire is held securely; cutting without support can lead to accidents.

Tips for Maintaining Your Tools

While you might be focused on using your tools effectively, maintaining them is just as essential for guaranteeing they last and operate smoothly.

First, clean your tools after each use; removing any dirt or debris helps prevent corrosion.

Next, regularly inspect for signs of wear or damage, like dull blades or frayed handles—address these issues promptly to avoid accidents.

Keep cutting edges sharp; this requires less force and results in cleaner cuts. Regular maintenance, including checking for rust, enhances the longevity and effectiveness of your tools.

Additionally, lubricate moving parts to make sure they function properly.

Finally, store your tools in a cool, dry place, ideally in a toolbox or on a designated pegboard.

Best Practices for Working With Electrical Connections

When working with electrical connections, following best practices can greatly reduce the risk of accidents and guarantee reliable performance.

To assure safety and effectiveness, keep these tips in mind:

- Always disconnect power before working on any electrical connection to prevent shock.

- Use proper insulation and connectors to prevent shorts and assure a secure connection.

- Double-check your work by testing connections after reassembly to verify correct functionality.

- Regular calibration of your tools is essential for ensuring accurate measurements, which can prevent dangerous errors while working on electrical connections.

When to Call a Professional Electrician

How can you tell if a job is best left to the pros? If you’re dealing with complex wiring, like updating an electrical panel or adding circuits, it’s time to call a professional electrician.

If you feel unsure about your knowledge of local building codes or safety regulations, hiring an expert is a smart move.

Additionally, if you notice flickering lights, frequent circuit breaker trips, or burning smells, don’t hesitate. These signs could indicate serious issues that require professional intervention.

Safety’s vital when working with electricity, and sometimes, it’s best not to take risks. Trusting your instincts can save you from accidents and costly repairs, so when in doubt, seek a qualified electrician to handle the task.

Questions

Can I Strip Wires Without Specialized Tools?

Yes, you can strip wires without specialized tools, but it’s risky. Using a sharp knife or scissors can work, but you might damage the wire or hurt yourself. It’s best to use the right tools.

What Should I Do if I Accidentally Cut a Wire?

If you’ve accidentally snipped a wire, think of a tree losing a branch. First, stop what you’re doing, inspect the damage, then reconnect it or replace it to keep things running smoothly. Safety’s key!

Is There a Safe Way to Reuse Stripped Wires?

Yes, you can safely reuse stripped wires. Just inspect them for damage, verify they’re clean, and make proper connections. If they’re too frayed or damaged, it’s best to replace them for safety.

How to Dispose of Old Wires Safely?

When you’re disposing of old wires, consider recycling them at an e-waste facility. For instance, a local community center hosted a recycling event last year, ensuring safe disposal while promoting environmental responsibility. It’s a win-win!

Can I Strip Wires While Wearing Gloves?

Yes, you can strip wires while wearing gloves. Just guarantee they’re the right type, providing enough dexterity for precision. This keeps you safe from sharp edges and electrical hazards during the process.

Conclusion

To sum up, by following the principles of safe wire stripping and cutting, you’ll greatly reduce the risk of accidents. Did you know that nearly 30% of electrical accidents are linked to improper handling of wires? Wearing the right safety gear and using the correct techniques can help you avoid these dangers. Always prioritize safety, keep your tools well-maintained, and don’t hesitate to call a professional if you’re unsure. Working smart not only protects you but also guarantees the job’s done right.